SAP Product Lifecycle Management (SAP PLM)

We have the expertise and tools to help you run your PLM program — frustration-free.

We Know Managing PLM Complexity Is a Daunting Task

Product lifecycle management is an easy-to-grasp concept. Come up with an idea, develop the concept, scale to production, then keep improving the product until eventually retiring it.

But the complexities involved can be staggering. From the sheer amount of product data and the number of participants and stakeholders to evolving regulations and continuous change management, all of these factors and more can cause a lot of frustration.

SAP PLM offers a time-tested suite of tools to manage your PLM program. But you also need expert help to align SAP's solutions with your organization's unique needs and ensure that your product lifecycle management is smooth and efficient across the board.

Understanding the Five Key Phases of PLM

Idea

This is where innovation begins. At the ideation stage, companies collect and manage product requirements, generate initiatives, and assess early-stage concepts. It’s about turning market needs, customer pain points, or new technologies into viable product ideas. SAP PLM enables structured requirement management and concept evaluation tools to ensure that the strongest ideas move forward.

Design

Once the concept is approved, the focus shifts to detailed design and engineering. This includes creating 2D/3D models, developing product structures, and managing recipes or formulations. Specifications are defined, simulations are run, and collaboration among design, R&D, and quality teams begins. SAP PLM integrates CAD tools and provides a single source of truth for all design data, ensuring smooth teamwork and version control.

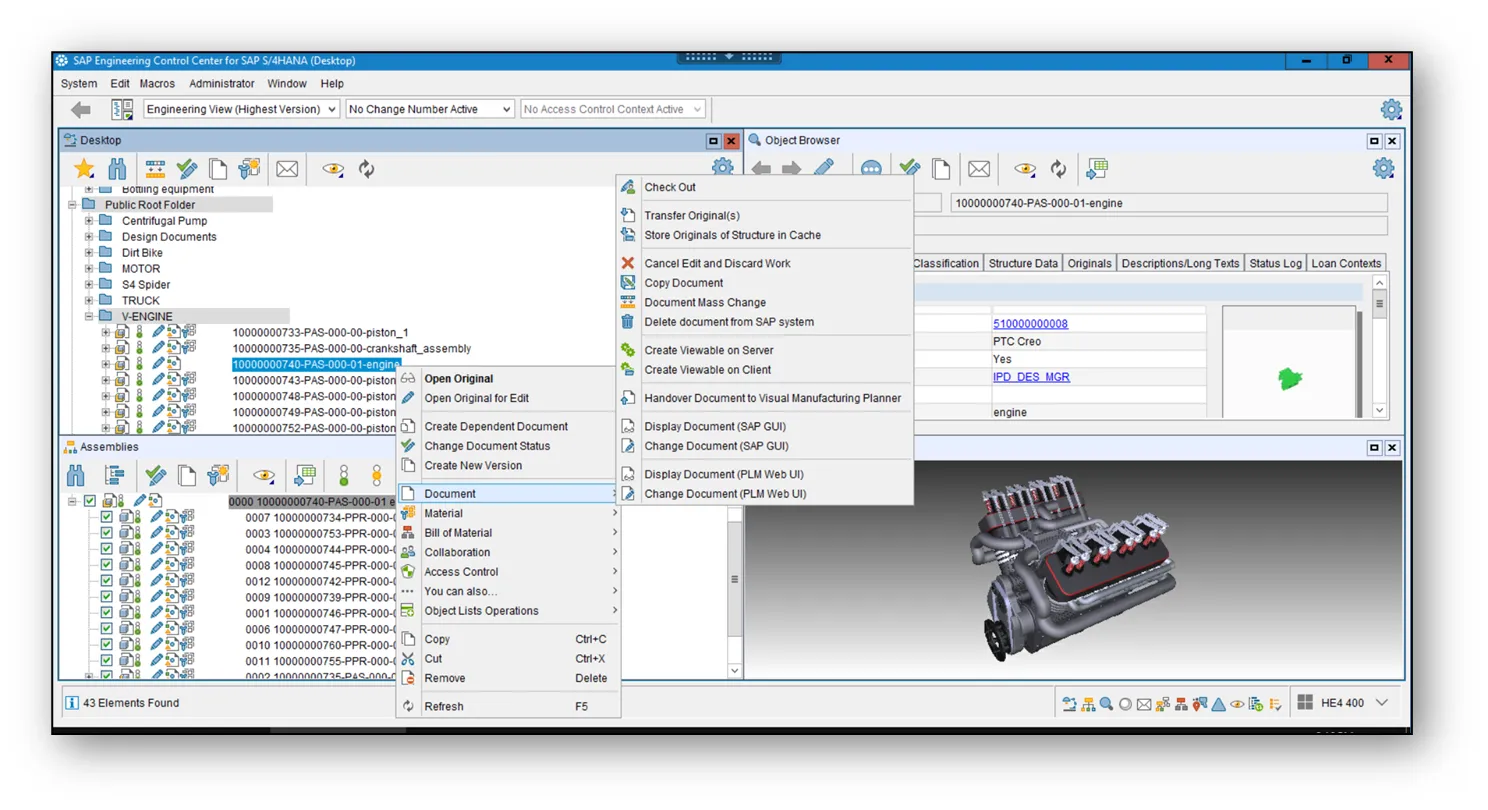

Manufacturing

After the design is finalized, it’s time to prepare for production. This involves creating Bills of Materials (BOMs), work instructions, and routing plans. SAP PLM ensures that all manufacturing data is accurate, synchronized, and accessible to downstream systems like ERP and MES. It bridges the gap between engineering and shop floor operations, reducing errors and accelerating time to production.

Service

Once the product reaches the market, the service phase begins. Here, the focus is on maintaining performance, supporting users, and managing repairs or upgrades. SAP PLM supports service documentation, tracks maintenance history, and enables feedback loops from the field. This real-time feedback is crucial for improving future product generations and enhancing customer satisfaction.

Disposal

Eventually, every product reaches the end of its lifecycle. In the disposal phase, companies must manage decommissioning, recycling, or environmentally responsible disposal. SAP PLM helps ensure compliance with sustainability goals and environmental regulations by tracking material content, hazardous substances, and end-of-life processes.

Take Control of Every Stage of Your Product Lifecycle

Synchronization

Change management

Optimization

Faster time to market

Reduced downtime and process inefficiencies

SAP PLM Services We Offer

Strategic PLM consulting

SAP PLM implementation

SAP PLM integrations

SAP PLM application management (AMS)

Security

Clients’ Success Stories

LeverX helped a construction machinery corporation increase efficiency by 25-35%

The LeverX team helped the customer streamline document management and product lifecycle management. We also helped the client to create a single source of truth which makes it easier to collaborate with other facilities.

BMAX & IPS intgration for JBS

Our team successfully integrated IPS & BMAX to transform master data creation for a food processing company.

Migration to SAP for a medical device manufacturer

LeverX assisted a medical device manufacturer in migration to SAP and workflow automation.

SAP PLM Solutions

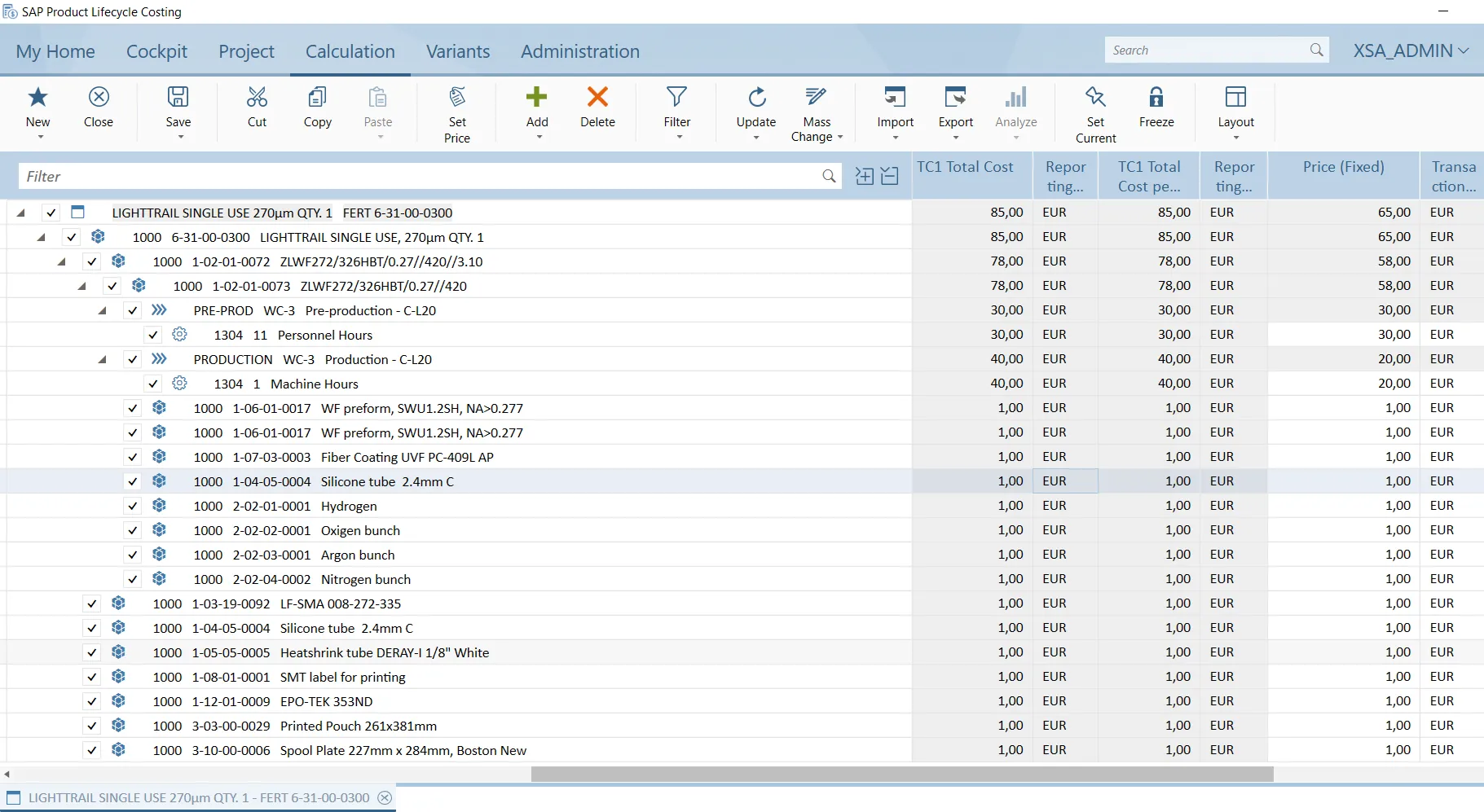

Product Design and Development

SAP PLM solutions for design and development drive innovation and collaboration across product lifecycles. These solutions:

- Accelerate design processes by integrating CAD tools with centralized product data.

- Enhance collaboration between teams with real-time access to design and engineering data.

- Improve visualization using 3D modeling and simulation for better decision-making.

Show more

-

Integrates CAD systems with SAP for seamless design management.

-

Provides 3D visualization tools and collaborative design capabilities.

-

Combines product data with interactive 3D visuals for better communication.

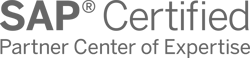

Cost Management and Regulatory Compliance

SAP PLM solutions ensure cost efficiency and adherence to safety and industry standards throughout the product lifecycle. These solutions:

- Simulate and control product costs to maintain profitability.

- Ensure regulatory compliance for safety, quality, and environmental standards.

- Facilitate audits and certifications by integrating compliance checks into workflows.

Show more

-

Tools to simulate and compare costs across lifecycle stages.

-

Manage formulations and ensure compliance with regulatory requirements.

-

Track hazardous substances and meet regulatory obligations.

Document and Data Management

SAP PLM solutions centralize and streamline document management to improve collaboration and reduce errors. These solutions:

- Centralize the storage of product-related documents for consistent data access.

- Enable secure document sharing between departments and external stakeholders.

- Enhance decision-making by ensuring the availability of accurate and up-to-date data.

Show more

-

Centralized platform for managing product documents.

-

Enables collaborative data sharing and document handling.

-

Streamlines the integration of product data across SAP environments without additional middleware.

Project and Portfolio Management

SAP PLM solutions for project and portfolio management ensure efficient resource allocation and successful project execution. These solutions help:

- Align projects with strategic goals by prioritizing resources and budgets.

- Identify and mitigate project risks early in the process.

- Optimize project portfolios to maximize ROI and resource utilization.

Show more

-

Offers tools for project prioritization, risk assessment, and resource planning.

Collaborative Product Development

SAP PLM solutions connect teams and external partners to streamline product development. These solutions:

- Enable real-time collaboration by providing centralized access to product data.

- Enhance supplier and partner coordination for faster development cycles.

- Reduce time-to-market by improving communication and task handoffs.

Show more

-

Facilitates real-time collaboration with 3D visualization tools.

-

SAP Business Network Collaboration

Enables seamless communication with suppliers and partners.

Life Sciences and Specialized Formulation Management

SAP PLM solutions for life sciences and formulation management streamline the creation and compliance of product formulations in highly regulated industries. These solutions:

- Optimize batch records to accelerate creation, review, and approval processes.

- Ensure compliance with industry-specific regulations for life sciences and chemicals.

- Foster innovation in formulations by managing data across departments and teams.

Show more

-

Simplifies batch record creation and ensures compliance with strict regulatory standards.

-

Enables the management and optimization of product formulations, ensuring compliance and quality throughout the lifecycle.

Sustainability in Product Lifecycle

SAP PLM solutions for sustainability integrate environmental and social goals into product development and management. These solutions:

- Track and report sustainability metrics to ensure compliance and transparency.

- Measure and optimize carbon footprints across product lifecycles.

- Support sustainable design with insights into material selection and lifecycle impacts.

Show more

-

Provides tools for sustainable product design and regulatory compliance.

-

Tracks environmental impacts across the value chain.

Change and Configuration Management

SAP PLM solutions for change and configuration management streamline workflows and maintain traceability. These solutions:

- Manage product modifications with clear change request workflows.

- Ensure version control for complex product configurations.

- Facilitate traceability from design to production.

Show more

-

Provides tools for managing product revisions and configurations.

-

Enables efficient engineering change management.

End-to-End Lifecycle Integration

SAP PLM solutions provide seamless integration across all stages of the product lifecycle, from design to disposal. These solutions:

- Synchronize engineering and manufacturing processes to improve operational efficiency.

- Integrate IoT and analytics to monitor product performance and enable predictive maintenance.

- Manage end-of-life transitions with workflows for recycling, reuse, and regulatory compliance.

Show more

-

SAP IoT and Analytics Integration:

Provides real-time insights into product performance and usage.

-

Ensures compliance during end-of-life management.

-

Facilitates integration between design, manufacturing, and operations.

Not Sure Which PLM Modules Are Right for You?

Accelerate Innovation with Intelligent Product Modeling

- Connect 2D and 3D product models to ERP systems for real-time access to relevant business information.

- Integrate process-related data swiftly and accurately, enhancing collaboration and innovation.

- Streamline product development with AI-driven insights that bridge design and business operations.

Use Our SAP PLM Accelerators for a Competitive Edge

IPS (Integrated Process Solution)

IPS is a user-friendly workflow solution that allows business users to build, modify, and deploy a wide variety of workflows and improve "time to complete".

LEARN MOREDataLark

DataLark is our proprietary solution that can significantly cut costs and improve efficiency of complex data migration and/or integration projects.

LEARN MOREBMAX (BOM Material Allocation Extension Tool)

BMAX is designed to automate the creation and extension of material masters and BOMs, improving operational efficiencies.

LEARN MOREIQ Product Work Center

IQ-PWC places critical data at your fingertips to enable better change management. With it, you can implement product design changes with minimal impact on business.

LEARN MOREIndustries We Serve

Leverx Is Your Trusted SAP PLM Partner

Proven track record

Industry experts

SAP partnership

Quality and security

Investment in innovation

Flexibility

Implementation Roadmap

- Current Processes Evaluation: Assess existing business processes and identify the organization's needs.

- Defining Technical Requirements: Create a detailed specification of the functional and technical needs of the new system.

Discover

- Setting Goals and Objectives: Establish and agree on the goals to be achieved throughout the project.

- Assembling the Project Team: Appoint team members and define their roles and responsibilities.

- Project Plan Development: Create a comprehensive plan that outlines project phases, timelines, resources, and key performance indicators.

- Budget Determination: Estimate and approve the budget.

- Specifications Preparation: Develop the technical and functional specifications for the development team.

Prepare

- Ensuring Business Requirements are Met: Check that SAP PLM aligns with business requirements and project objectives.

- Data Validation: Verify the accuracy and compliance of the data.

Explore

- Data Migration: Transfer data from existing systems to the new one.

- System Configuration: Set up the solution according to requirements and specifications.

- Customization: Develop additional features and modules, if the standard solution does not meet all needs.

- Integrations: Configure SAP PLM to work with other IT systems and applications.

Realize

- Testing: Perform functional, integration, regression, and load testing to ensure that all works correctly.

- User Training: Organize sessions to help users become familiar with the new system.

Deploy

- System Readiness Check: Verify that the system is ready for operational use.

- Launch: Officially transition to active use of SAP PLM.

- Ongoing Support: Continuously monitor solution performance to identify and resolve any issues.

Run

Insights From Our Blog

All highlights

PLM Implementation Advice Every Business Owner Should Know About

Adopt SAP PLM for end-to-end product development and production. Check this article to learn PLM implementation expert-proven tips for your business!

How Data Silos Slowly Disrupt Your Business and How to Avoid It

What are data silos, why are they harmful to businesses, and is there a cure-all? SAP and LeverX experts answer the questions in the dedicated collaborative article and offer solutions that could help you improve data management efficiency.

How PLM Drives Innovation in the Turbulent Reality

SAP and LeverX Experts on the Industry Trends and Future of Product Lifecycle Management. We've interviewed two PLM experts.

FAQ

What is SAP PLM?

Is SAP PLM scalable for growing product portfolios or global operations?

What types of support and training does LeverX provide for PLM solution users?

How can my organization start using SAP PLM with LeverX?

How user-friendly is SAP PLM for non-technical users?

SAP PLM features intuitive interfaces, visual dashboards, and guided workflows that make it accessible to business users as well as technical teams. With proper training and customization, even non-engineering stakeholders can efficiently interact with product data.

Contact Us

What happens next?

-

1

An expert will reach out to you to discuss your specific needs and requirements.

-

2

We'll sign an NDA to ensure any sensitive information is kept secure and confidential.

-

3

We'll work with you to prepare a customized proposal based on the project's scope, timeline, and budget.

years of expertise

projects

professionals

Contact Us

CONTACT US

If you are looking for an SAP Global Strategic Supplier or Technology Partner for your business, fill out the form below, and we will contact you at short notice.