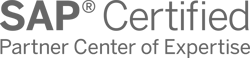

SAP Production Planning and Detailed Scheduling

Reduce order lead time, ensure optimal resource usage, and increase production volumes with efficient production planning.

Creation of Executable Production Plans Comes True

SAP Production Planning and Detailed Scheduling (SAP PP/DS) is a convenient solution for optimization and detailed planning (short-term, medium-term, and related to a final product release). This component allows you to resolve complex planning and scheduling scenarios.

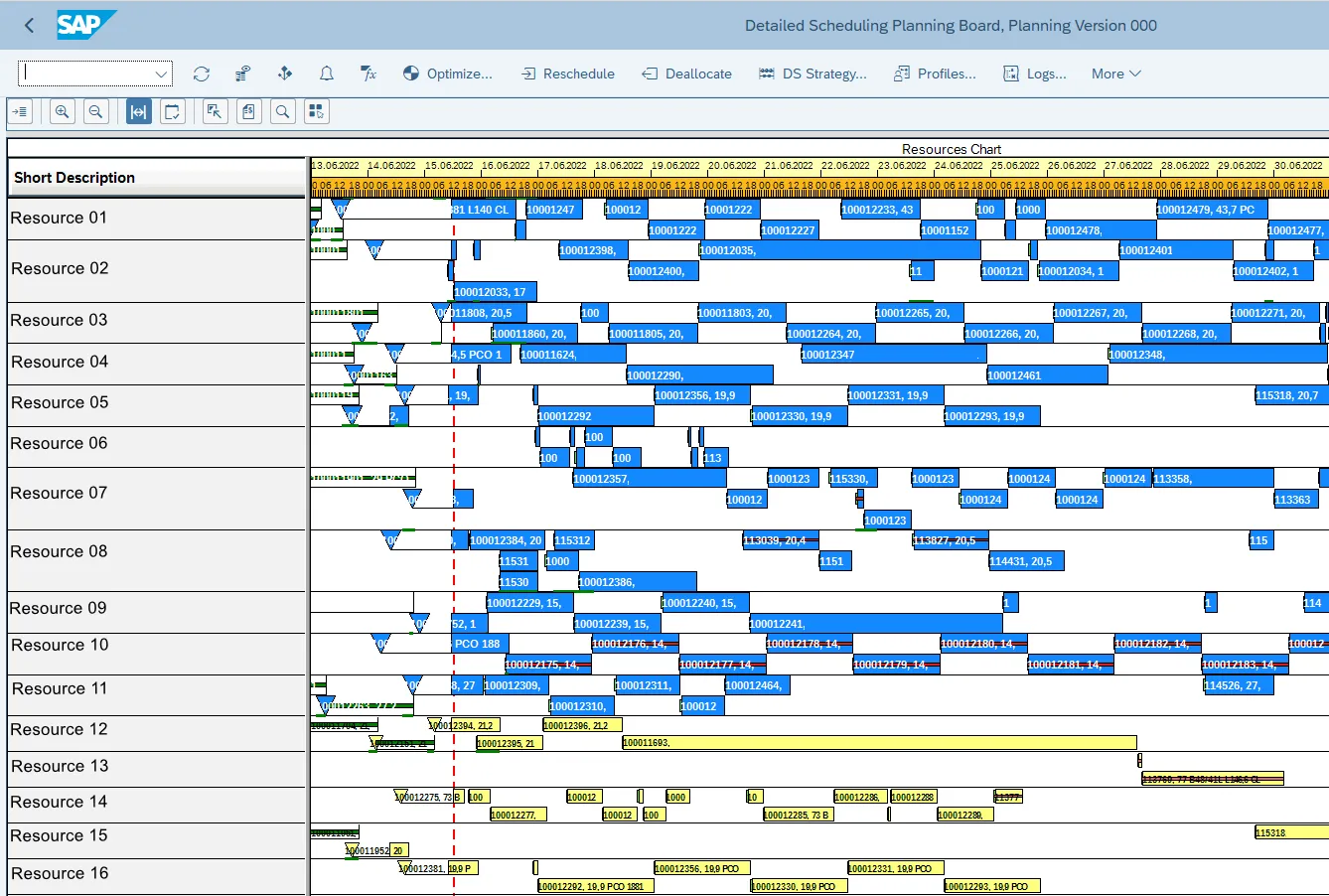

Product Planning Table interface

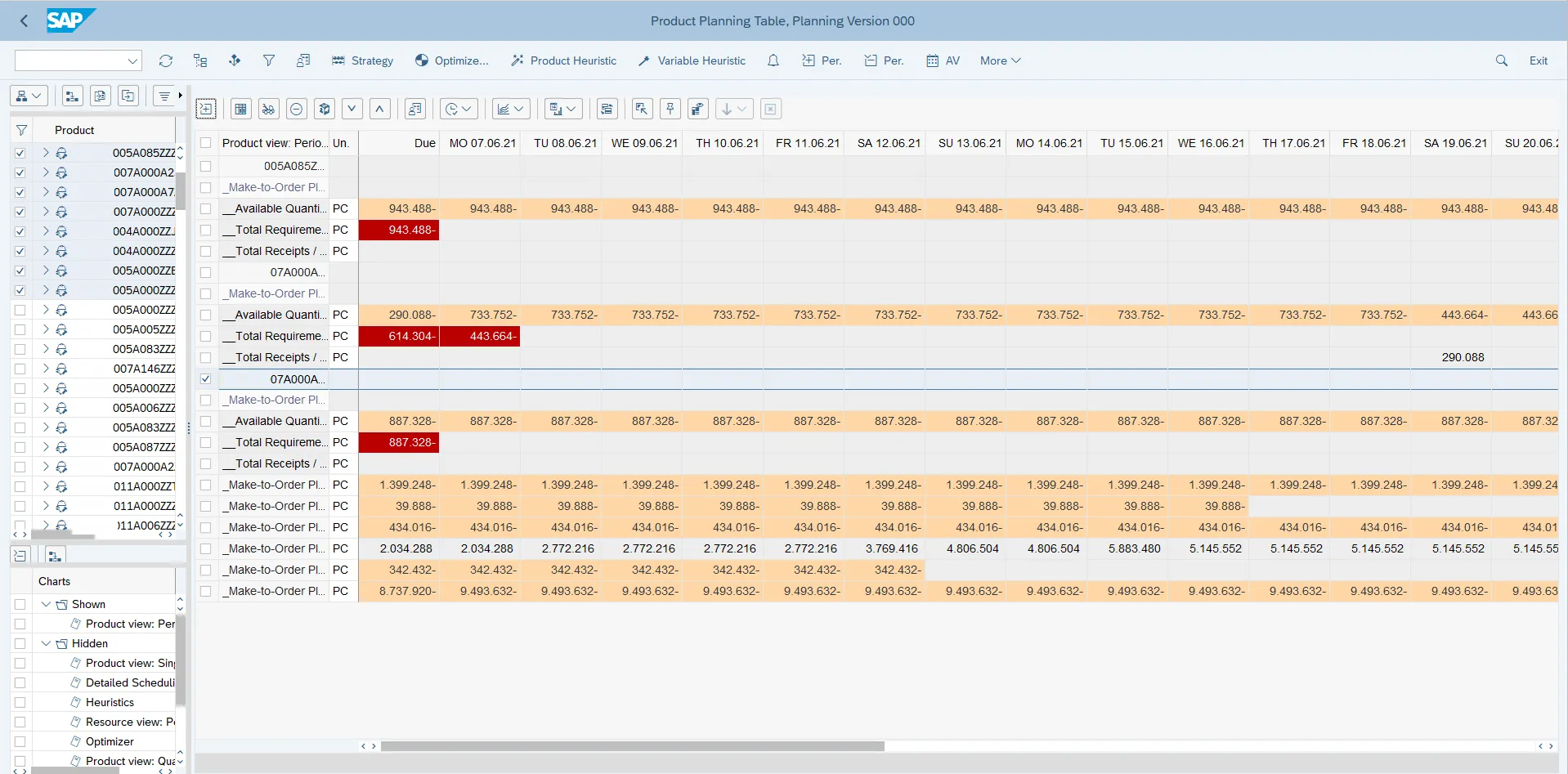

The interface of the optimization tool in SAP PP/DS

How Can SAP PP/DS Help Your Business?

Process planning simplification

Order lead time reduction

Output growth

Storage costs reduction

Resources optimization

On-time delivery

What Business Issues Does SAP PP/DS Help Overcome?

Planning

- Planning actions for each product

- Interactive planning

- Automatic planning

- Short-term, medium-term, and long-term planning

Heuristics

- Planning for selected objects using a particular algorithm

- Material planning with finite capacity planning

- Resolving supply and demand problems

- Resolving capacity problems

Optimization

- Decreasing manufacturing lead time

- Minimizing setup costs and time

- Reducing delays

Pegging relationships

- Create relationships between supply and demand elements based on the planning situation

- Respect order relationships during scheduling to avoid quantity and date/time issues

Alert Monitor

- Monitor the accuracy of the production plan and schedule

- Proactively monitor for any supply chain issues

- Identify exception situations and send notifications to the users

What Manufacturing Models Does SAP PP/DS Cover?

Make to stock

Plan and schedule your production based on forecasted product demand.

Make to order

Plan and schedule your production based on your customer demand.

Engineer to order

Design and produce products for the most demanding clients.

Project manufacturing

Organize efficient production planning regardless of your production scale.

Flow manufacturing

Plan the work step-by-step from start to completion, without delays or mistakes.

How We Can Help

Consulting

Implementation

Integration

Support

Application management

SAP PP/DS Integrations

SAP PP/DS works best when it’s connected to the systems that feed it real inputs: demand, materials, and what’s actually happening on the shop floor. When those links are in place, plans stop being “the ideal version” and start matching day-to-day reality.

- SAP S/4HANA: This is a core transactional and master data system for SAP PP/DS, not just a synchronization layer. Accurate PP/DS planning depends on timely and high-quality S/4HANA master data, order statuses, and inventory updates.

- SAP Integrated Business Planning (SAP IBP): SAP IBP supports mid- to long-term planning. It doesn’t do detailed scheduling, but it sets demand and supply plans (volumes, priorities, and constraints) that SAP PP/DS then breaks down, sequences, and schedules in detail.

- SAP Extended Warehouse Management (SAP EWM): Helps the warehouse stay in sync with production. Materials get staged on time, so the line doesn’t sit and wait.

- SAP Manufacturing Execution System (SAP MES): SAP MES feeds near-real-time execution updates into planning, so PP/DS can reschedule quickly when production slips, stops, or changes — not just during the next daily planning cycle.

- SAP Quality Management (SAP QM): It sets the real limits that PP/DS has to work with and affects what PP/DS can plan by updating availability, such as quality holds, usage decisions, or blocked stock, ensuring the schedule reflects real constraints.

Industries We Serve

Why Choose LeverX as Your SAP Implementation Provider?

Proven track record

Industry experts

SAP partnership

Quality and security track record

Investment in innovation

Flexibility

Customers' success stories

LeverX Helped A Construction Machinery Corporation Increase Efficiency by 25-35%

The LeverX team helped the customer streamline document management and product lifecycle management. We also helped the client to create a single source of truth which makes it easier to collaborate with other facilities.

SAP Workflow Implementation for an Automobile Manufacturer

Implementation of an automated system that would allow coordinating budget expenditures for a large automobile manufacturer.

want to view more our cases?

SAP PLM Journey for a Manufacturer of Dispensed Beverage Equipment

The LeverX team assisted the customer with a phased approach to SAP PLM.

R&D/Engineering Modernization for a Consumer Good Manufacturer

We have transformed and modernized the R&D/Engineering and Product Lifecycle Management for the customer to efficiently manage the product’s lifecycle, engineer, and manufacture its products at the highest level while continuing to innovate.

WANT TO VIEW MORE OUR CASES?

Fintech Solution Development for a Group of Banks

LeverX provided the client with several solutions that ensure smooth bank performance in several ways, from the provision of additional security to the facilitation of operations and improved revenue growth.

Data science solution development for the fintech sector

Merchant recognition solution based on ML.

WANT TO VIEW MORE OUR CASES?

SAP Transportation Management Implementation for a Transport Company

LeverX helped a large transport company to achieve transparent reporting, reduce transportation costs, and optimize routes with SAP TM.

SAP Yard Logistics Implementation and Adaptation for a Railway Company

LeverX delivered the analytical, reporting, and planning powers of the SAP Yard Logistics system.

WANT TO VIEW MORE OUR CASES?

Revolutionizing Distributors' Sales Performance With Analytics Platform

LeverX — Emerline developed a comprehensive sales analytics platform with numerous modules and integrated it with SAP to streamline distributors' operations and help them optimize their performance.

SAP Transportation Management Implementation for a Large Retailer

The LeverX team of experts helped a retail company implement SAP TM, thereby automating transport processes and significantly improving the company's key performance indicators.

WANT TO VIEW MORE OUR CASES?

Solution Development for Leveraging the Power of SAP S/4HANA and SAP BTP

LeverX helped develop a solution to automate and improve the clinical supplies process and gain better visibility into the status of clinical supplies worldwide.

PLM Digital Transformation For Hygiene And Infection Prevention Company

We helped the customer reduce cycle times and increase capacity, allowing manufacturing to begin sooner.

WANT TO VIEW MORE OUR CASES?

Implementation Roadmap

- Current Processes Evaluation: Assess existing business processes and identify the organization's needs.

- Defining Technical Requirements: Create a detailed specification of the functional and technical needs of the new system.

Discover

- Setting Goals and Objectives: Establish and agree on the goals to be achieved throughout the project.

- Assembling the Project Team: Appoint team members and define their roles and responsibilities.

- Project Plan Development: Create a comprehensive plan that outlines project phases, timelines, resources, and key performance indicators.

- Budget Determination: Estimate and approve the budget.

- Specifications Preparation: Develop the technical and functional specifications for the development team.

Prepare

- Ensuring Business Requirements are Met: Check that SAP PP/DS aligns with business requirements and project objectives.

- Data Validation: Verify the accuracy and compliance of the data.

Explore

- Data Migration: Transfer data from existing systems to the new one.

- System Configuration: Set up the solution according to requirements and specifications.

- Customization: Develop additional features and modules, if the standard solution does not meet all needs.

- Integrations: Configure SAP PP/DS to work with other IT systems and applications.

Realize

- Testing: Perform functional, integration, regression, and load testing to ensure that all works correctly.

- User Training: Organize sessions to help users become familiar with the new system.

Deploy

- System Readiness Check: Verify that the system is ready for operational use.

- Launch: Officially transition to active use of SAP PP/DS.

- Ongoing Support: Continuously monitor solution performance to identify and resolve any issues.

Run

FAQ

What is SAP PP/DS?

Can SAP PP/DS integrate with SAP S/4HANA?

Is SAP PP/DS cloud-compatible?

Can SAP PP/DS help with demand fluctuations?

How does SAP PP/DS improve overall production efficiency?

Can SAP Detailed Scheduling (DS) optimize production schedules based on machine capacities, labor availability, and material constraints?

Contact Us

What happens next?

-

1

An expert will reach out to you to discuss your specific needs and requirements.

-

2

We'll sign an NDA to ensure any sensitive information is kept secure and confidential.

-

3

We'll work with you to prepare a customized proposal based on the project's scope, timeline, and budget.

years of expertise

projects

professionals

Contact Us

CONTACT US

If you are looking for an SAP Global Strategic Supplier or Technology Partner for your business, fill out the form below, and we will contact you at short notice.