Let’s look at the logistics trends that will shape the industry from 2025 to 2030 — and what they could mean for your business.

Five years after COVID-19 upended global trade, one thing is crystal clear: supply chains can break fast — and when they do, business doesn’t just slow down, it stalls. Now that the global economy is finding its footing again, logistics is moving into a new chapter. It’s no longer about getting back to normal. It’s about building supply chains that can bounce back, run smarter, and adapt on the fly.

According to McKinsey research, logistics companies continue investing heavily in digital technologies to reduce costs, increase productivity, and future-proof operations. Over the next five years, these investments will shift from basic digitalization toward intelligent, interconnected supply chain ecosystems.

Let’s look at the logistics trends that will shape the industry from 2025 to 2030 — and what they could mean for your business.

From Digital to Autonomous Supply Chains

Digital logistics isn’t a differentiator anymore — it’s simply expected. Through 2030, the winners will be the ones with supply chains that can keep moving — and keep adjusting — without a lot of manual work.

These days, Warehouse Management Systems (WMS) and transport platforms can tell you where your inventory is, where your trucks are, and what’s happening on the warehouse floor in real time. What’s changing in 2025–2030 is that AI won’t just report the problem; it will help fix it by adjusting routes, shifting stock, and responding early to disruptions.

What this means for your business:

- Reduced dependency on manual planning and firefighting

- Faster response to demand fluctuations and disruptions

- Higher service levels with lower operational costs

Transparency as a Business Standard

Visibility used to be a competitive edge. It’s simply the standard that customers and partners expect now. With real-time visibility into inventory, shipments, and suppliers, you can spot issues early and stay ahead of disruptions instead of scrambling to fix them.

With cloud WMS, it’s already easy to see inventory levels across sites in real time. Over 2025–2030, that visibility will matter even more — not just for operations, but for compliance, sustainability reporting, and smoother collaboration with partners.

What this means for your business:

- Accurate inventory levels prevent shortages and overstocking

- Predictive analytics identify risks before they disrupt operations

- Shared data improves collaboration with partners and customers

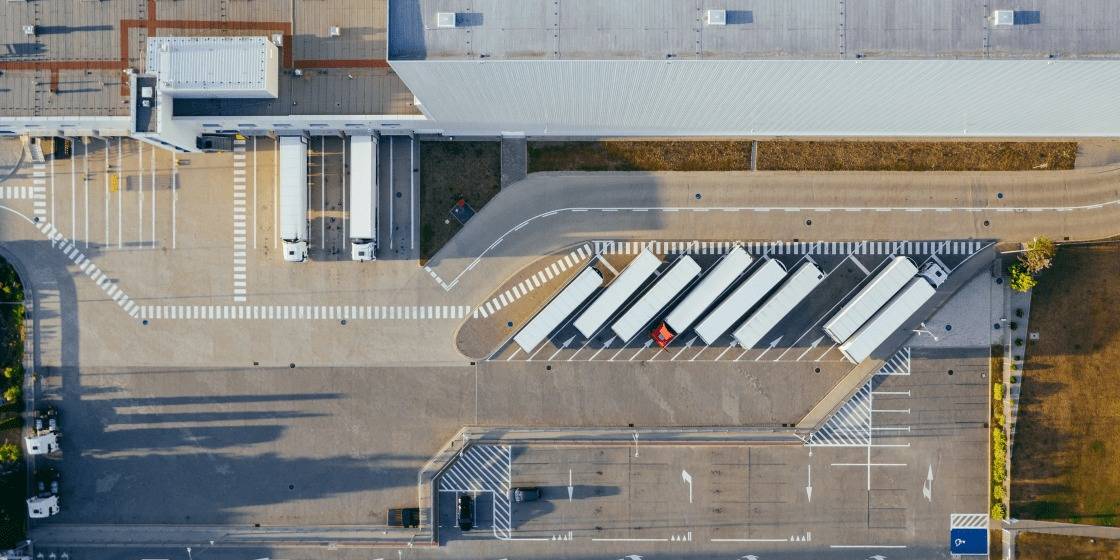

Logistics Automation at Scale

Automation is reshaping logistics far beyond the warehouse — it’s now changing how yards, ports, and major transport hubs operate, too.

Automation helps warehouses move more orders with the same team and keep accuracy high when volumes spike. Modern AI-powered robots can perform up to 1,000 orders, picking operations per hour with high accuracy.

What this means for your business:

- Scalable operations without proportional labor growth

- Faster order processing during peak seasons

- Improved safety and operational consistency

Omnichannel and B2B Commerce 2.0

B2B logistics is rapidly evolving. Business customers now expect the same speed, transparency, and convenience as in B2C — combined with complex pricing, contracts, and delivery models.

Digital platforms connect your logistics operations with online sales channels, making subscriptions, automated ordering, and real-time stock visibility much easier to run.

What this means for your business:

- Automated order placement through digital catalogs

- CRM integration for tracking customer interactions, personalizing offers, and streamlining sales management

- Personalized interfaces, automated invoicing, and instant order confirmations

- Real-time integration between sales channels and logistics

AI as a Core Supply Chain Capability

AI will stay central to logistics in 2025–2030. AI-driven software improvements — from autonomous code generation to system modernization — take routine work off specialists’ plates and help planning become more accurate.

Gartner expects adoption to accelerate fast: by 2026, more than 80% of enterprises will have used generative AI APIs or models or deployed GenAI-enabled applications in production, up from under 5% in 2023.

What this means for your business:

- Faster and more accurate decision-making

- Adaptive planning based on real-time data

- Greater operational flexibility in volatile markets

Faster and Smarter Direct Delivery

With customers expecting speed, companies are bringing inventory closer to demand and offering more ways to receive or return orders — all to cut delivery times and add flexibility.

Last-mile innovation also includes drone delivery.

What this means for your business:

- Faster deliveries through decentralized fulfillment

- Flexible ordering and returns across channels

- Reduced transportation costs for small, urgent shipments

Machine Customers and Algorithmic Procurement

Machine customers — AI-driven systems that autonomously place orders — are emerging as a powerful force in logistics. Examples range from industrial equipment ordering spare parts to household devices replenishing consumables.

Gartner predicts that machine customers will have an impact even greater than the rise of E-commerce.

What this means for your business:

- Automated replenishment aligned with real consumption

- Reduced procurement delays and errors

- API-first logistics and real-time integration requirements

Cloud as the Backbone of Modern Logistics

With the cloud, logistics isn’t locked inside on-prem systems anymore. SaaS tools make it easier to see transportation and inventory data in real time — wherever your team is.

Scalability, automatic updates, and lower infrastructure costs make the cloud a strong fit for long-term growth.

How this benefits your business:

- Faster adoption of new capabilities

- Global access to logistics data

- Infrastructure that scales with demand

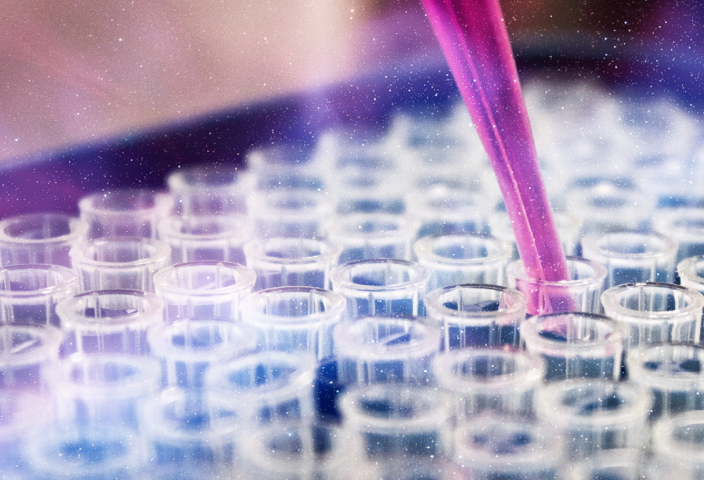

IoT-Driven Cargo Monitoring

IoT devices monitor shipment location and conditions like temperature and humidity during transport — a must for sensitive goods such as pharma, food, and chemicals. That visibility reduces losses, prevents damage, and strengthens customer trust.

How this benefits your business:

- Real-time condition monitoring and alerts

- Reduced losses from spoilage or damage

- Transparent shipment tracking for customers

Cyber-Resilient Supply Chains

As logistics goes digital, cyber risk rises with it. In 2024 alone, supply chain cyberattacks affected around 183,000 companies worldwide.

From 2025 to 2030, the goal won’t be “perfect protection” — it will be cyber resilience: making sure your operations can keep running even if an incident happens.

How this benefits your business:

- Less downtime: fewer disruptions and faster recovery when something goes wrong

- Stronger data protection: better safeguards for sensitive operational and partner information

- Easier compliance: security controls that keep pace with tightening regulations and customer requirements

Digital Twins as a Control Tower Foundation

A digital twin is basically a virtual version of your logistics operation. It lets teams test “what if” scenarios, fine-tune processes, and catch risks early — so planning feels less like guesswork, and disruptions are easier to handle.

How this benefits your business:

- Proactive risk mitigation

- Optimized resource allocation

- Faster and more confident decision-making

Blockchain for Trust and Transparency

Blockchain helps keep supply chain data honest and consistent by creating a shared record that can’t be quietly changed later. Each event — a status update, a handoff, a temperature reading — is logged and can be viewed by everyone who needs it, from carriers to customers.

Between 2024 and 2032, blockchain adoption in logistics is expected to grow rapidly, with forecasts pointing to over 39% CAGR.

How this benefits your business:

- Tamper-proof documentation: fewer disputes, clearer accountability

- Faster data reconciliation: less time chasing mismatched records across systems

- More trust across the network: partners and customers can rely on the same source of truth

Multimodal and Sustainable Logistics

Instead of treating trucking, rail, ocean, and air as separate worlds, multimodal platforms tie them together. And in parallel, sustainability is becoming something companies have to report on and pay attention to. CO₂ tracking, green routing, and emissions reporting increasingly influence logistics decisions.

How this benefits your business:

- Flexible route and mode selection

- Lower transportation costs

- Compliance with ESG requirements

Why Companies Fail to Implement These Trends

Even though the benefits are clear, many logistics transformation programs still fall short. In 2025–2030, the biggest blockers won’t be the technology — they’ll be misaligned teams, fragmented systems, and unclear priorities.

Here are the most common reasons companies struggle to turn modern logistics capabilities into real results.

Technology-first thinking without business context

Organizations often invest in AI, robotics, and digital twins without clearly defining the expected business outcomes. As a result, these initiatives experience limited adoption, poor alignment with operational objectives, or fail to scale beyond the proof-of-concept stage.

Why does this happen?

- Lack of measurable business objectives

- Innovation driven by trends rather than value

- Limited involvement of operations teams

Fragmented IT landscapes and poor integration

Logistics IT is often a patchwork of legacy systems, regional solutions, and partner platforms. Without a unified architecture, it’s hard to get end-to-end value, no matter how advanced the tools are. Data silos get in the way of real-time visibility, fast decisions, and automation.

Typical symptoms:

- Manual data clean-up and reconciliation

- Slow or inconsistent reporting

- No foundation for real-time or autonomous operations

Low data quality and weak data governance

AI in logistics and predictive planning only works as well as the data behind it. Many companies underestimate the work it takes to get data governance right — consistent master data, clear ownership, and basic discipline. When the data can’t be trusted, analytics can’t be trusted either, and teams quickly revert to manual workarounds.

Resistance to change and skills gaps

Logistics transformation reshapes daily work: processes, roles, and responsibilities. If change management is weak, teams are slow to adopt new tools, and old workarounds return. Meanwhile, automation and AI demand new skills — from overseeing systems to making decisions based on data — and many organizations can’t develop them fast enough.

Overlooking cyber and operational risk

As logistics networks become more connected, cyber risk and operational dependencies increase. When security and resilience aren’t built in from the start, vulnerabilities appear that can disrupt operations, expose sensitive data, and damage trust with partners and customers.

Lack of industry-specific perspective

What works in retail won’t necessarily work in pharma, and that’s where generic solutions fall apart. If industry requirements come second, projects stall or underdeliver. Industry context is what helps you prioritize the right use cases and design for scale.

Overambitious scope and unrealistic timelines

Large programs fail when ambition outpaces resources, and timelines are unrealistic. Strong teams take a phased approach: deliver value in small wins, then scale what works.

How to Prioritize These Trends for Your Business

Not every trend will be relevant for every company — and you don’t need to tackle everything at once. What to start with depends on your goals, your current setup, and the issues that slow your operation down today. This section can help you turn priorities into a practical plan.

1. Start with where you are today

Start by looking at how logistics really runs day to day. How much of the work is still manual? How often do people have to pass tasks back and forth between teams or systems? And can you quickly answer the basics — what’s available, where shipments are, and how much capacity you actually have? If visibility is limited and processes feel fragmented, the first step is usually to get reliable end-to-end visibility and cut down on manual work. If the basics are already in place but planning is still slow or uneven, focus next on improving planning and speeding up execution. And if operations are already stable and connected, you can move toward broader automation and more advanced capabilities across sites and partners.

2. Tie priorities to your main business goal

What you prioritize depends on your goal. For cost, reduce manual effort, improve warehouse and transport utilization, and eliminate rework caused by errors and data mismatches. For service, concentrate on faster delivery, higher reliability, and better tracking and communication. If resilience is the driver, invest in stronger disruption response and less reliance on manual coordination. And if compliance or sustainability is the central pressure, strengthen traceability, reporting, and control over what happens across the network.

3. Factor in your industry requirements

Industry context shapes both priorities and what “good” looks like. Manufacturing often needs tighter coordination with production, smoother yard and warehouse operations, and stronger supplier alignment. Retail and FMCG typically prioritize fast replenishment, forecasting for peaks, and flexible fulfillment and returns. Life sciences and chemicals require strict traceability, condition monitoring, and audit-ready processes. Logistics service providers, meanwhile, focus on partner connectivity, multimodal coordination, and scalable operations that can flex with demand.

4. Check your data and integrations before you scale

Many initiatives slow down not because the tools are wrong, but because the foundation isn’t ready. If data is inconsistent across systems or integrations depend on manual fixes, advanced capabilities won’t hold up in real operations. Readiness usually means the same numbers align across core systems, responsibilities for maintaining data are clear, and connections with partners and platforms work reliably enough to support timely, consistent processes.

5. Build in phases with use cases you can repeat

A phased approach tends to work better than one large program. Start with a small number of use cases that show measurable results in a reasonable time, can be rolled out across locations or regions, and create a base for the next steps. This reduces risk, supports adoption, and helps you build long-term capabilities without taking on more than the organization can realistically deliver.

The best priorities match your goals, your starting point, and your industry realities. A phased approach keeps progress steady and makes scaling easier.

Outpace Competitors with SAP Supply Chain Capabilities

Supply chains don’t fall apart because teams aren’t working hard — they fall apart when plans don’t match reality. Demand changes overnight, carriers miss slots, inventory ends up in the wrong place, and suddenly everyone is reacting instead of running the operation. To stay competitive, companies need more than “on-time execution.” They need better planning, tighter control over assets and costs, and the ability to meet sustainability and compliance expectations without drowning in manual work.

SAP helps by connecting the moving parts — planning, warehousing, transportation, supplier collaboration, and customer delivery — in one landscape. Instead of jumping between separate tools and spreadsheets, teams can work with the same data and see what’s happening across sites and partners in near real time. That speeds up day-to-day decisions, makes exceptions easier to handle, and disruptions less painful.

SAP Digital Supply Chain (DSC) is the umbrella for these capabilities. It’s not a single product — it’s SAP’s supply chain portfolio brought together to support end-to-end processes: planning, manufacturing, and logistics execution, asset operations, and collaboration across the network. When these pieces are set up as one working system, companies can spot issues earlier, keep supply and demand in balance, and improve performance continuously.

What businesses typically get from SAP Digital Supply Chain:

- Faster planning cycles and quicker response when demand shifts

- More accurate inventory and fewer “surprises” across locations

- Higher throughput without having to grow headcount at the same pace

- Stronger traceability, transparency, and control across the logistics network

With SAP Digital Supply Chain in place, logistics becomes easier to manage — not because it gets simpler, but because you finally have the visibility and coordination to stay ahead of problems instead of chasing them.

How LeverX Can Help

If you're looking to improve logistics processes and streamline supply chain management, LeverX's experts are ready to assist you.

LeverX implements various systems that help:

- Optimize warehouse operations and route planning.

- Accelerate delivery processes.

- Integrate systems with external platforms.

- Migrate data between systems.

Our mission is to automate processes, making it easier for you to control every stage of delivery.

LeverX’s tailored solutions deliver results such as:

- Faster order processing.

- Reduced transportation and storage costs.

- Enhanced supply chain transparency and control.

- Minimized risks and improved forecasting.

Our Hands-On Expertise with SAP Logistics Solutions

LeverX and Girteka optimized HR processes with SAP SuccessFactors

In collaboration with SAP, LeverX implemented SAP SuccessFactors in Girteka, one of Europe's largest FTL companies. Automation streamlined HR processes, improved data analysis, and boosted productivity.

The project was started with modules for HR management, recruitment, onboarding, performance, and shift planning at the Lithuanian office. The second phase extended the solution to other countries, incorporating new modules.

SAP SuccessFactors enhanced processes, improved employee mobility, and established a foundation for growth.

LeverX implemented SAP Yard Logistics to optimize port operations

A European port was challenged with the need to manage increasing workloads. LeverX implemented SAP Yard Logistics with features like automated berth reservation, optimized vessel routing, and task distribution. The system was integrated with MRS and Solver for better visualization and resource management.

Outcomes included faster loading/unloading processes, reduced manual labor, and improved planning transparency. As a result, the planning efficiency increased, and process management became streamlined and transparent.

LeverX helped a transport company reduce costs and optimize routes with SAP TM

A leading European transport company faced the need to improve logistics, simplify data processing, and enhance reporting efficiency. To address these challenges, LeverX implemented SAP TM, configuring the system for ferry transportation and integrating it with truck tracking and route management solutions. This significantly improved route optimization and interaction with carriers.

After implementing the solution, the company achieved detailed reporting, increased transparency in all logistics operations, and enhanced transportation management. Additionally, transportation costs were reduced through more efficient financial resource utilization and automation of real-time event tracking with SAP Event Management.

Implementation of SAP EHS improved employee health and safety

A global logistics giant with over 300,000 employees turned to LeverX to modernize its health and safety systems. The solution included enhancing medical examination schedules, as well as managing risks and chemical substances. Our team customized SAP EHS by developing a Fiori calendar for scheduling medical appointments, introducing a new risk analysis method based on the EMKG scheme, and creating a chemical interface for importing data from external sources.

The implementation of these components helped improve employee health prevention and hazardous materials management, as well as accelerate risk assessment processes. For instance, the EMKG method enabled a more precise determination of hazard levels, while the specialized interface became a key tool for handling chemical data. Additionally, these solutions strengthened the company's image as a responsible employer.

Conclusion

From 2025 to 2030, logistics will keep shifting toward autonomous decision support, network visibility, scalable automation, and stronger cyber resilience. Companies that invest in the right foundation — data, integration, and adoption — will be able to move faster, serve customers better, and absorb disruption without stalling operations.

How useful was this article?

Thanks for your feedback!

.jpg)

-min-2.jpg)