In this article, we will consider supply chain bottlenecks in the pharmaceutical industry and tell how SAP solutions can help overcome them.

5 Ways Pharma Companies Can Make Supply Chain Management More Resilient

According to an IDC report, more than 70% of pharmaceutical companies faced supply chain vulnerabilities in 2020. In the first few months of that year, as the COVID-19 pandemic was gaining momentum worldwide, it reduced the in-full delivery of medicines by nearly 50%.

Of course, all industries face supply chain disruptions today. But there is no room for mistakes in the pharmaceutical industry because the cost of failure may be human lives.

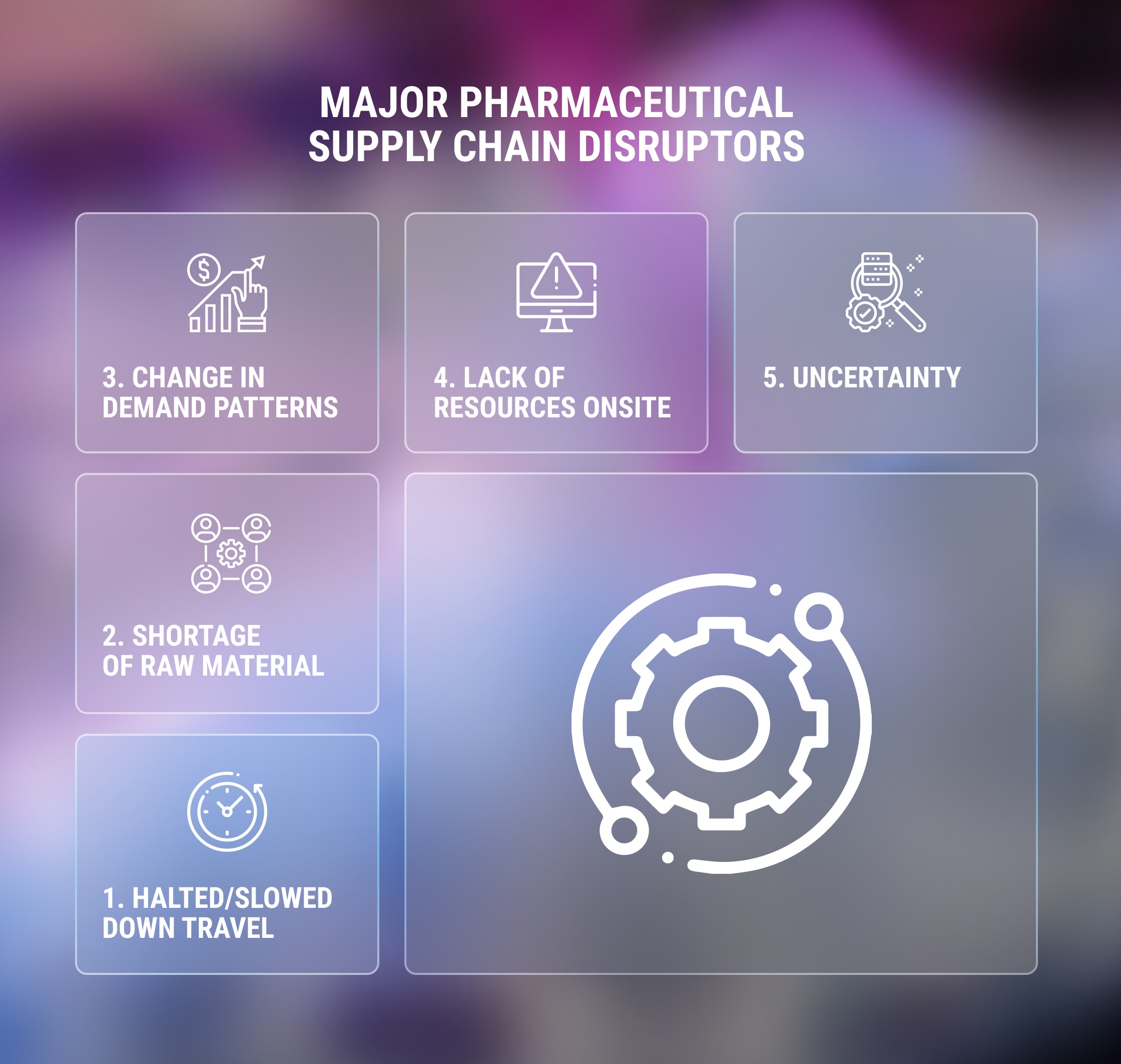

This article tells about seven pharma supply chain challenges of 2022 and five SAP solutions that can be implemented to address them.

#1 Demand Forecasting

The COVID-19 pandemic has again demonstrated that demand forecasting is one of the biggest challenges of supply chain management in pharmaceutical industry. To produce and deliver products on time, it is crucial to ensure the continuous availability of raw materials, insurance stocks, or extra supply channels.

However, challenges with purchasing raw materials can be caused not only by material requirement planning errors but also by the material shortage per se and the labor requirements. These challenges significantly impact the productivity of companies that manufacture pharma components and ingredients.

How сan SAP help?

The pharma companies cannot influence labor and material shortage in companies involved in raw material extraction. But they can ensure effective demand forecasting and planning with SAP S/4HANA Cloud.

SAP S/4HANA Cloud is an intelligent cloud ERP system that offers characteristic-based segmentation to match supply and demand, and control materials, etc. With this software, you get ready-to-work processes built on proven industry best practices.

SAP S/4HANA Cloud can be implemented as standalone software or as a core of the RISE with SAP package.

#2 Just-In-Time Inventory

Another issue pharma supply chains face today is balancing portfolio-based inventory optimization and customer demand. Since pharmaceutical products cannot be stored for extended periods, many companies use a just-in-time inventory model. It requires working closely with suppliers so that raw materials arrive as production is scheduled to begin, but no sooner.

COVID-19 has demonstrated this model's vulnerability and the supply chain risks that lead to disruptions.

How can SAP help?

In this case, SAP Extended Warehouse Management (EWM) can help your business. This solution offers:

- Manual process automation

- Traceability of goods and materials

- Transparency of management and accounting processes

- Increased quality of warehouse operations

- Control of raw material availability and usage

#3 OTIF Risks

On-time in-full (OTIF) delivery is a common standard in the pharma industry today. If a company cannot enforce it, it is safe to say this leads to disrupted supplies. To comply with a supply agreement's terms, pharma companies are often forced to prepare extra cargo. It significantly increases transport and all other related costs — labor, fuel, and packaging.

In this case, manufacturers and sellers may also need clarification regarding delivery timeliness and completeness since they often have differing views on these indicators. The result is penalties for non-performance by partners.

How can SAP help?

For supply chain management and all related processes, SAP offers the SAP Digital Supply Chain (DSC) solution, covering logistics, manufacturing, planning, and operation needs. With this solution, you can save on freight costs, optimize cash flow, and enhance shipping processes.

Here are some real world examples of what you can achieve with SAP DSC:

- 87.5% faster delivery planning

- Increased transparency in the formation of the cost of freight transportation and distribution of costs

- Growth in productivity and quality through the centralization of tariffs and charge management

- 50% faster order processing and product availability

#4 Limited Supplier Network

Supply trends in recent years have demonstrated that the supply chain network cannot be limited to a few suppliers, even if they have been tested over the years. But today, some companies still cooperate with only a couple of suppliers, justifying this by cost efficiency.

However, this is somewhat misleading. Relying on a small group of suppliers without diversifying may result in critical supply chain vulnerabilities. While an extensive network covering several geographical regions increases production flexibility and ensures a smooth supply chain even in times of crisis.

How can SAP help?

Poor collaboration and lack of sustainability and purpose can be addressed with the SAP Ariba solution. It simplifies cooperation between buyers and suppliers and helps efficiently manage procurement processes, including buying and invoicing, supply chain collaboration, sourcing, supplier management, contract management, and catalog management.

After implementing SAP Ariba, you can achieve the following:

- 75% faster transaction cycles

- 60% lower operational costs on average

- 60% better accuracy of order processing

- 20% quicker cash collection from customers

- 15% higher customer retention rate

#5 Lack of Visibility

According to the Europol report, pharma products are the seventh most commonly seized counterfeit products worldwide. And the trade in falsified pharmaceuticals is continuing to grow. Due to increased geographies, faster lead times, limited visibility, and greater product variability, supply chains become more complex and create havoc for anti-counterfeiting efforts.

Pharma companies must receive real-time data on the status, timelines, and location of their products, raw materials, and sub-components.

How can SAP help?

To ensure visibility across the supply chain, pharmaceutical companies use SAP Advanced Track and Trace (ATTP) for Pharmaceuticals. This solution captures, tracks all necessary information about the cargo, and increases shipping accuracy and expenditure control within one cloud-based platform.

SAP ATTP enables the management of all serialization and regulatory data with partners, customers, and regulatory authorities. It also protects consumer safety through proper labeling management of packaging processes.

#6 Real-Time Data Collection

The previous point brings us to another problem facing the modern pharma industry. This is real-time data collection. The lack of supply chain data and real-time analytics makes it impossible for companies to take timely actions in case of disruptions.

The lack of real-time data complicates resource allocation that would ensure efficient order processing and compliance with OTIF criteria.

How can SAP help?

SAP S/4HANA Cloud offers powerful tools to collect and analyze data across the company. It collects data from all available sources, and due to the in-memory database, data processing takes just a few seconds. Moreover, data volumes don't matter.

An in-memory database is a new data storage approach that increases productivity and improves business users’ efficiency.

#7 Regulation Differences Across Borders

Pharma is one of the most regulated industries globally with many strict rules and regulations, which can differ depending on the region or countries for supply. Many of these regulations apply to packaging temperature and humidity, labeling, and handling. Maintaining compliance with all these rules and regulations is a challenging task.

Moreover, pharma companies must keep a strict record of the shipment statuses and report to regulatory authorities, which also have their requirements depending on the region.

How can SAP help?

You can comply with international and regional legislation with SAP ATTP for Pharmaceuticals, which provides a corporate serialization repository, serial number management, and regulatory reporting capabilities.

With this application, you can also boost the efficiency of your supply chain and reduce compliance costs for existing and upcoming serialization requirements.

Wrapping up

The COVID-19 outbreak and the various geopolitical events we are experiencing today have radically changed the modern market and are constantly testing business strength with new challenges. Inventory issues, lack of visibility, poor cooperation with suppliers, and regulatory challenges are just some of the problems pharmaceutical companies face. But you can be confident in your company’s future with reliable SAP software.

Contact our experts if you have questions about SAP solution capabilities and their benefits for your business!

How useful was this article?

Thanks for your feedback!

.jpg)