SAP Digital Manufacturing (SAP DM)

Optimize manufacturing performance by integrating production execution, visibility, and analysis.

Reliable Bridge Between Production and a Supply Chain

SAP Digital Manufacturing (SAP DM) is a cloud-based solution to execute manufacturing processes, plan production orders, and analyze scenarios. It is intended to help production supervisors and workers optimize processes and distribute the workload.

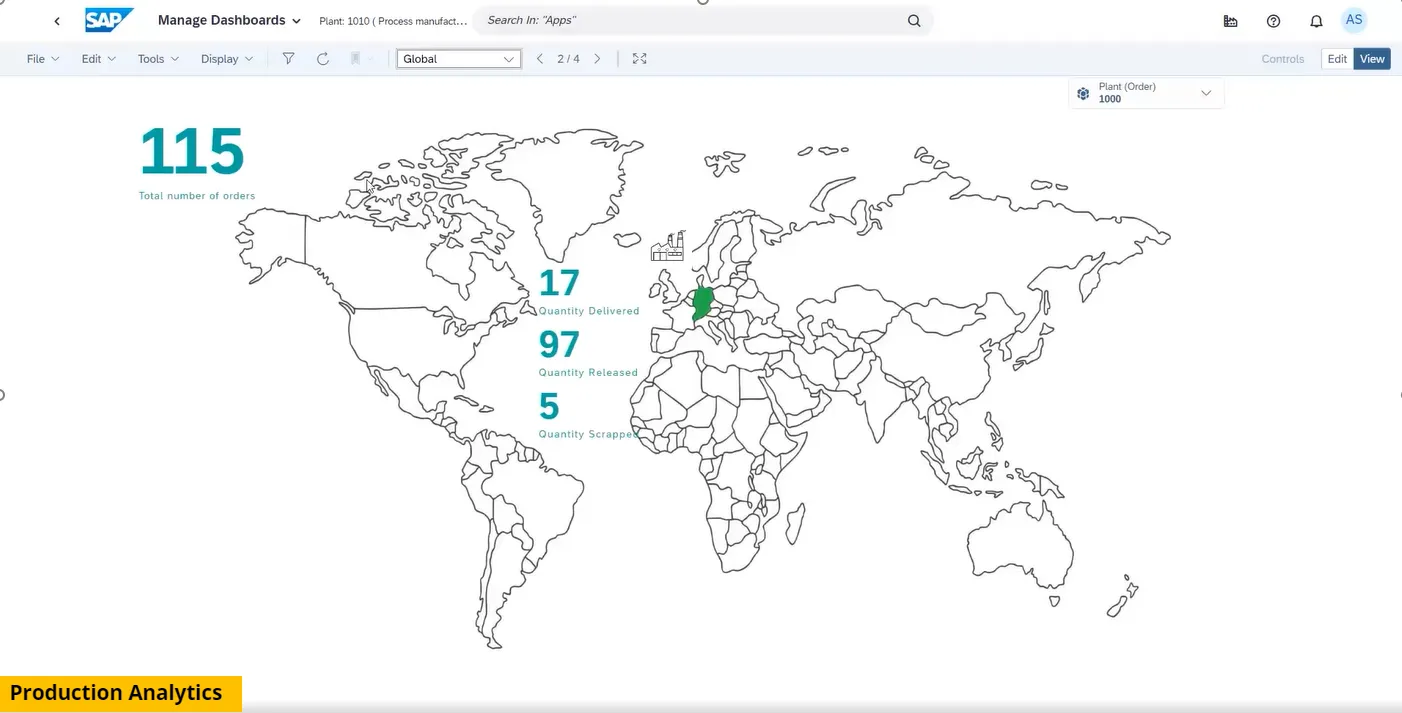

SAP DM is suitable for companies with branches in different countries and regions. This solution provides access to real-time analytics and business insights for each branch and the entire company.

Key SAP DM Modules

SAP Digital Manufacturing for Execution

SAP Digital Manufacturing for Insights

SAP Digital Manufacturing Resource Orchestration

How Can SAP DM Help Your Business?

Performance improvement

Consistent insights

Faster production line customization

Manufacturing automation

Effective execution

Resource management

What Challenges Does SAP DM Help to Overcome?

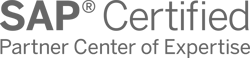

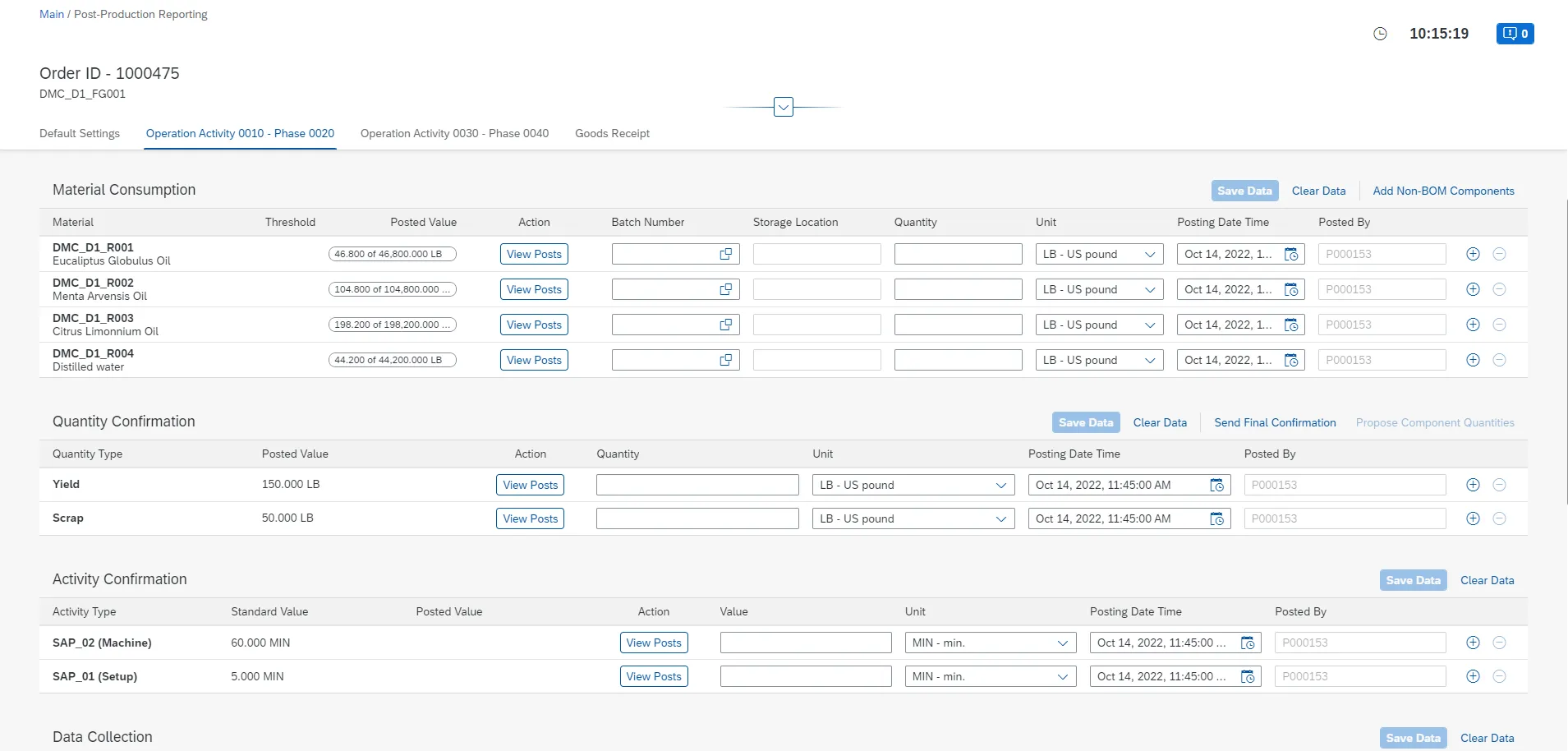

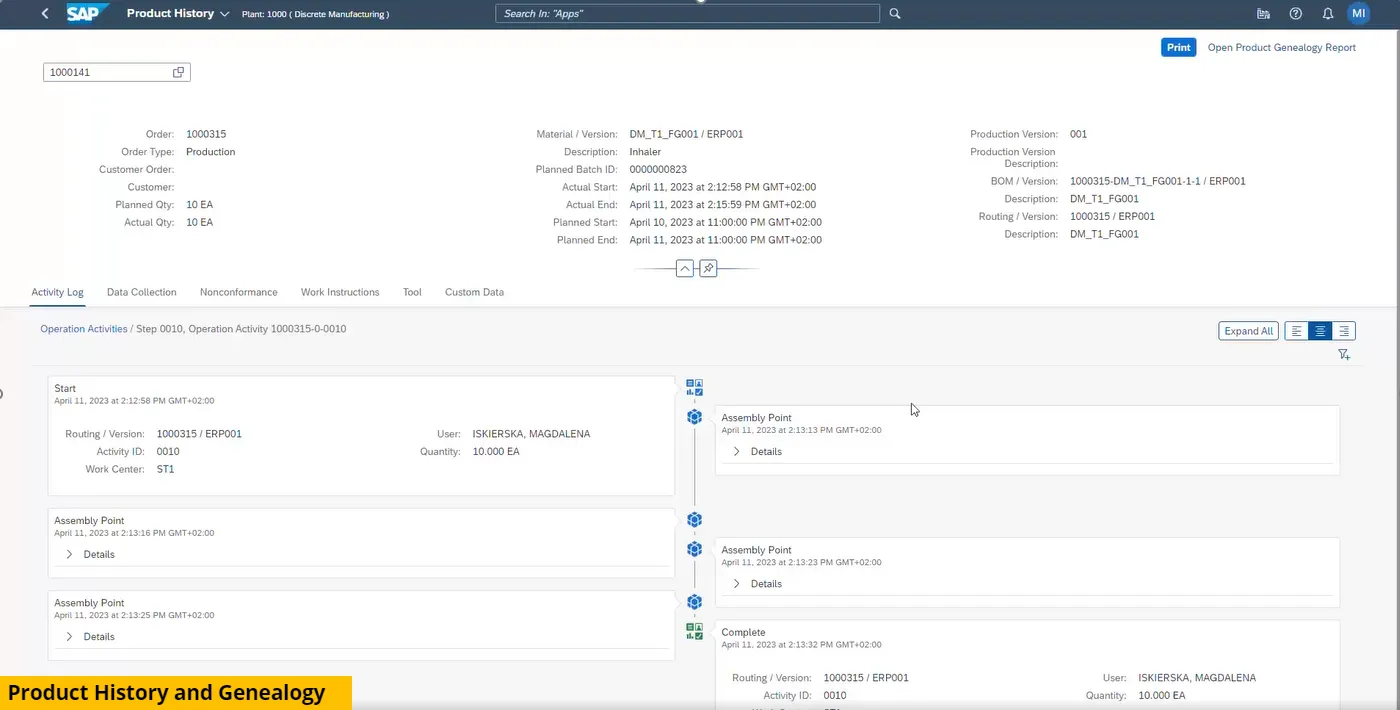

Work-in-process management

- Graphical routing engine to define the production flow

- Order release and status management

- Routing operation activities to start and complete orders

- Access to data on BOM

- Production activity history for an order

Nonconformance

- Nonconformance recording to indicate production deviations

- Nonconformance status tracking

- Visual inspection of manufactured materials, enabled by machine learning

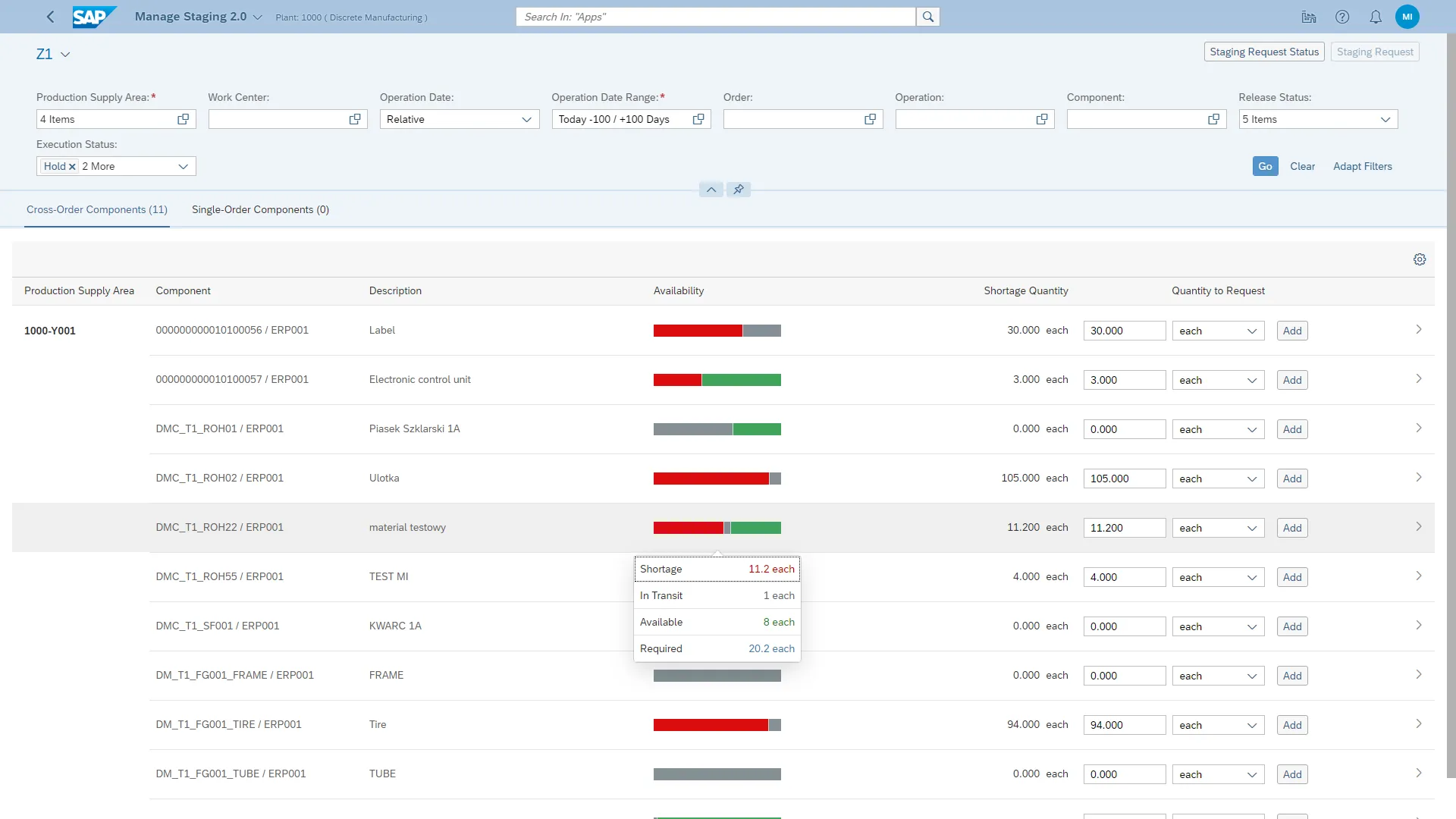

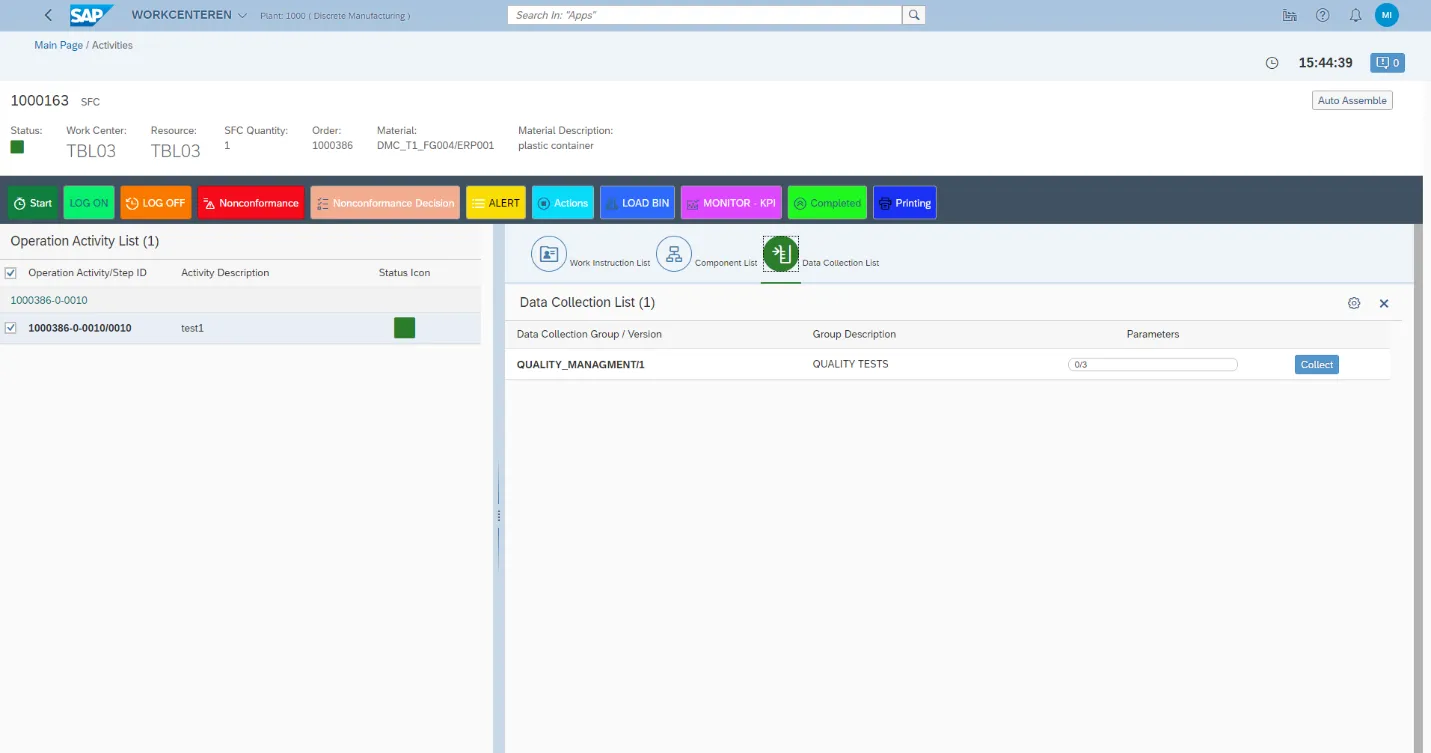

Data collection

- Definition of data collection criteria, their types, and limits

- Data collection from production UI

- System warnings when the criteria are outside the minimum and maximum limits

Data management

- Data replication from on-premise systems (SAP ECC, SAP S/4HANA)

- Simultaneous creation of multiple data models

- Access to plant data from SAP Digital Manufacturing for the execution of KPI calculations and analytics

Process order execution

- Process order execution with single and multiple batches

- Integration with SAP S/4HANA Cloud to replicate process orders, materials, material classifications, work centers, BOMs, batch numbers, recipes, and production versions

- Material consumption reports

- Scrap confirmation

- Post-production reporting of order execution data

Monitoring

- Production progress display

- Resource breakdown

- Integration with SAP Manufacturing Execution System to monitor failed messages

- POD integration

- Maintenance order overview with planned start and end date

- Alternate resources overview

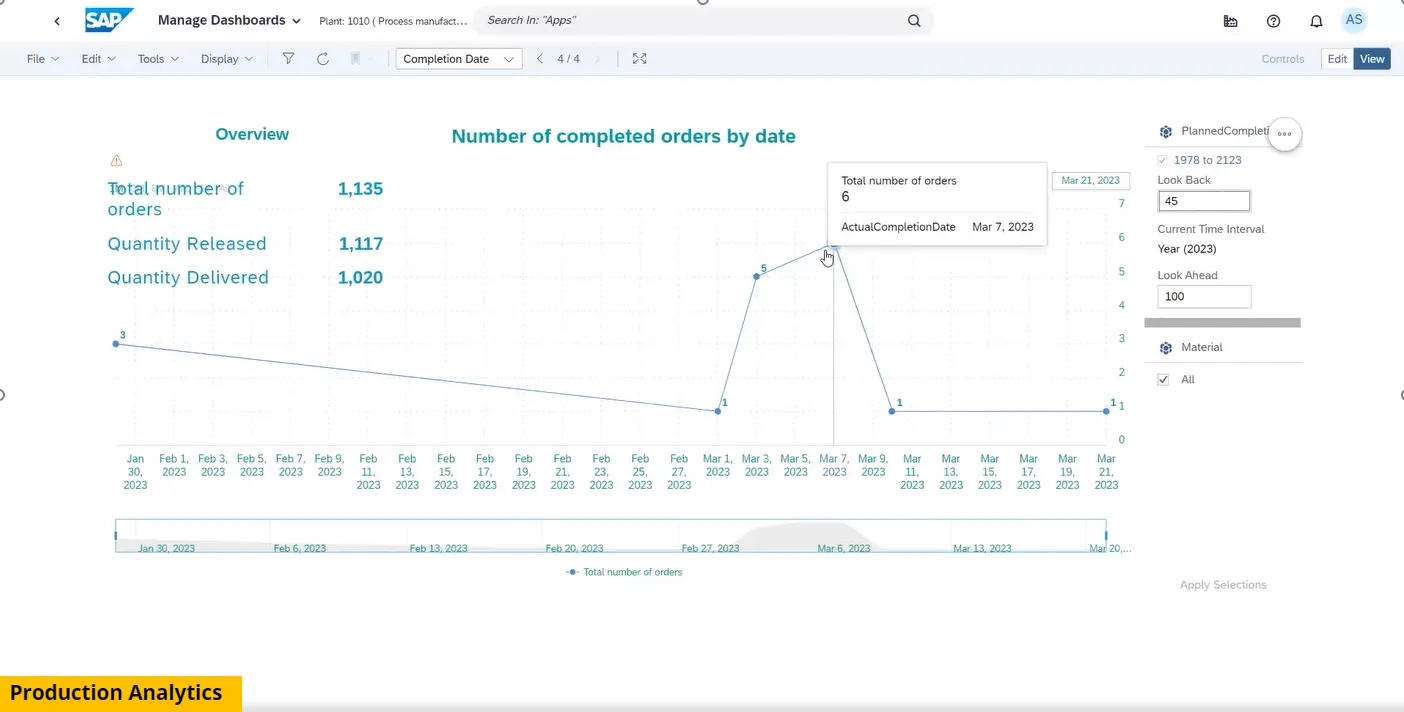

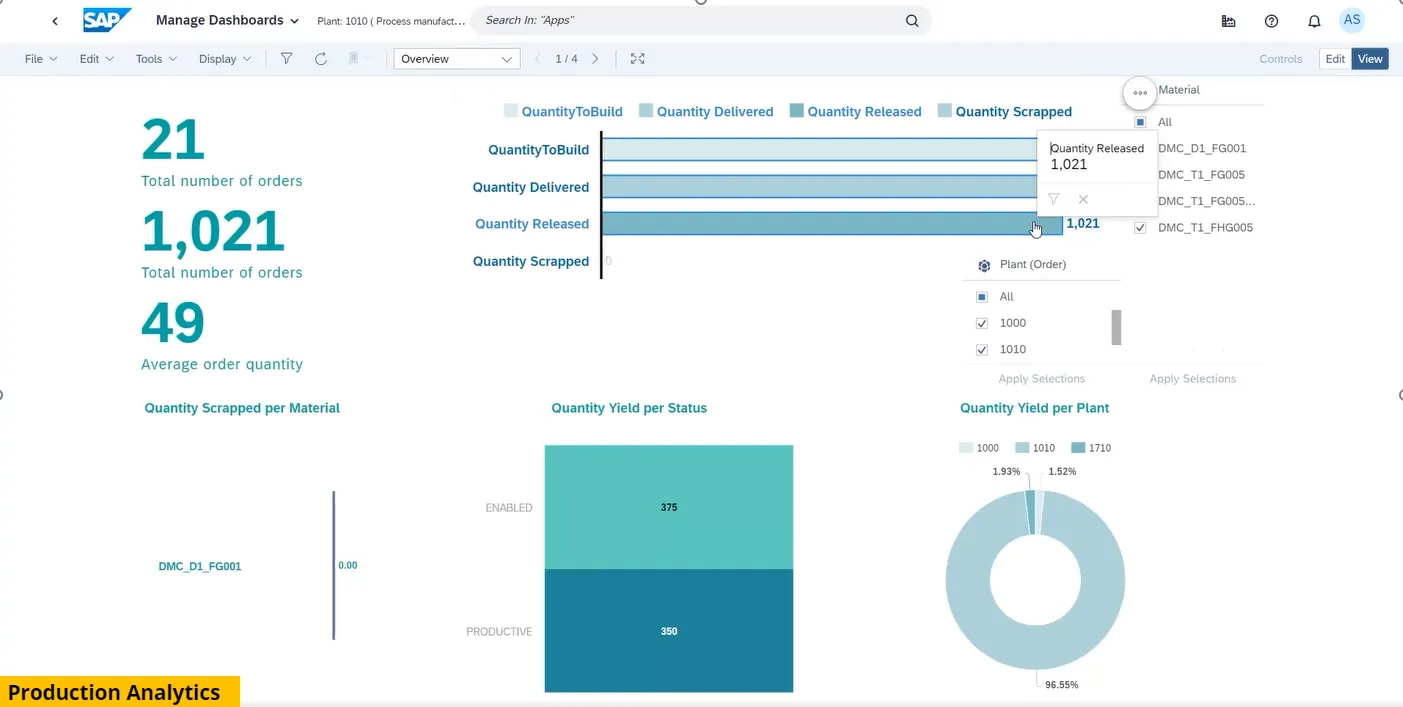

Analytics and insights

- KPI thresholds definition across and within several manufacturing plants

- Data filter according to time ranges

- Near real-time analytics on custom KPIs

- Global overview of standard and custom KPIs defined for all products produced across several manufacturing plants

- Comparison and analysis of work orders completed in production work centers compared to planned work orders

How Does SAP DM Work?

Manufacturing

a large-scale production

Manufacturing/ business

Insights

How We Can Help

Consulting

Implementation

Integration

Support

Application management

Systems You Can Integrate SAP DM With

You can strengthen your manufacturing environment by connecting SAP DM with other systems.

- SAP S/4HANA: Maintains the big production picture by synchronizing master data, keeping the information about production orders current in SAP DM, and reflecting production confirmations and material use to ensure financial postings and inventory updates are accurate.

- SAP Extended Warehouse Management (SAP EWM): Removes the guesswork during the planning of inventory movements by receiving the information about material staging and consumption and the work progress in manufacturing.

- SAP Quality Management (SAP QM): Checks the results and supports deviation detection in manufacturing processes, acting as the system of record for enterprise quality processes, and unifies quality and production data to facilitate compliance and traceability.

- SAP Enterprise Asset Management (SAP EAM): Informs maintenance teams on the actual machine usage and the technical details in case of any issues, according to machine operators, which helps extend the asset lifecycle.

- Shop floor systems and industrial IoT: Immediately provide data on temperature changes, vibrations, and other updates related to machinery directly to SAP DM, improving transparency and eliminating manual effort with errors.

Industries We Serve

Why Choose LeverX as Your SAP Implementation Provider?

Proven track record

Industry experts

SAP partnership

Quality and security

Investment in innovation

Flexibility

Implementation Roadmap

- Current Processes Evaluation: Assess existing business processes and identify the organization's needs.

- Defining Technical Requirements: Create a detailed specification of the functional and technical needs of the new system.

Discover

- Setting Goals and Objectives: Establish and agree on the goals to be achieved throughout the project.

- Assembling the Project Team: Appoint team members and define their roles and responsibilities.

- Project Plan Development: Create a comprehensive plan that outlines project phases, timelines, resources, and key performance indicators.

- Budget Determination: Estimate and approve the budget.

- Specifications Preparation: Develop the technical and functional specifications for the development team.

Prepare

- Ensuring Business Requirements are Met: Check that SAP DM aligns with business requirements and project objectives.

- Data Validation: Verify the accuracy and compliance of the data.

Explore

- Data Migration: Transfer data from existing systems to the new one.

- System Configuration: Set up the solution according to requirements and specifications.

- Customization: Develop additional features and modules, if the standard solution does not meet all needs.

- Integrations: Configure SAP DM to work with other IT systems and applications.

Realize

- Testing: Perform functional, integration, regression, and load testing to ensure that all works correctly.

- User Training: Organize sessions to help users become familiar with the new system.

Deploy

- System Readiness Check: Verify that the system is ready for operational use.

- Launch: Officially transition to active use of SAP DM.

- Ongoing Support: Continuously monitor solution performance to identify and resolve any issues.

Run

FAQ

What is SAP Digital Manufacturing (DM)?

How does SAP DM enhance manufacturing efficiency?

Is SAP DM a cloud-only solution?

How does SAP DM support IoT and Industry 4.0?

Can SAP DM integrate with SAP ERP and SAP S/4HANA?

How does SAP DM support quality management?

Does SAP DM provide production analytics?

Contact Us

What happens next?

-

1

An expert will reach out to you to discuss your specific needs and requirements.

-

2

We'll sign an NDA to ensure any sensitive information is kept secure and confidential.

-

3

We'll work with you to prepare a customized proposal based on the project's scope, timeline, and budget.

years of expertise

projects

professionals

Contact Us

CONTACT US

If you are looking for an SAP Global Strategic Supplier or Technology Partner for your business, fill out the form below, and we will contact you at short notice.