SAP Digital Manufacturing Cloud

Integrate production execution, insight, and analysis to improve manufacturing performance.

A dependable link between supply chain and production

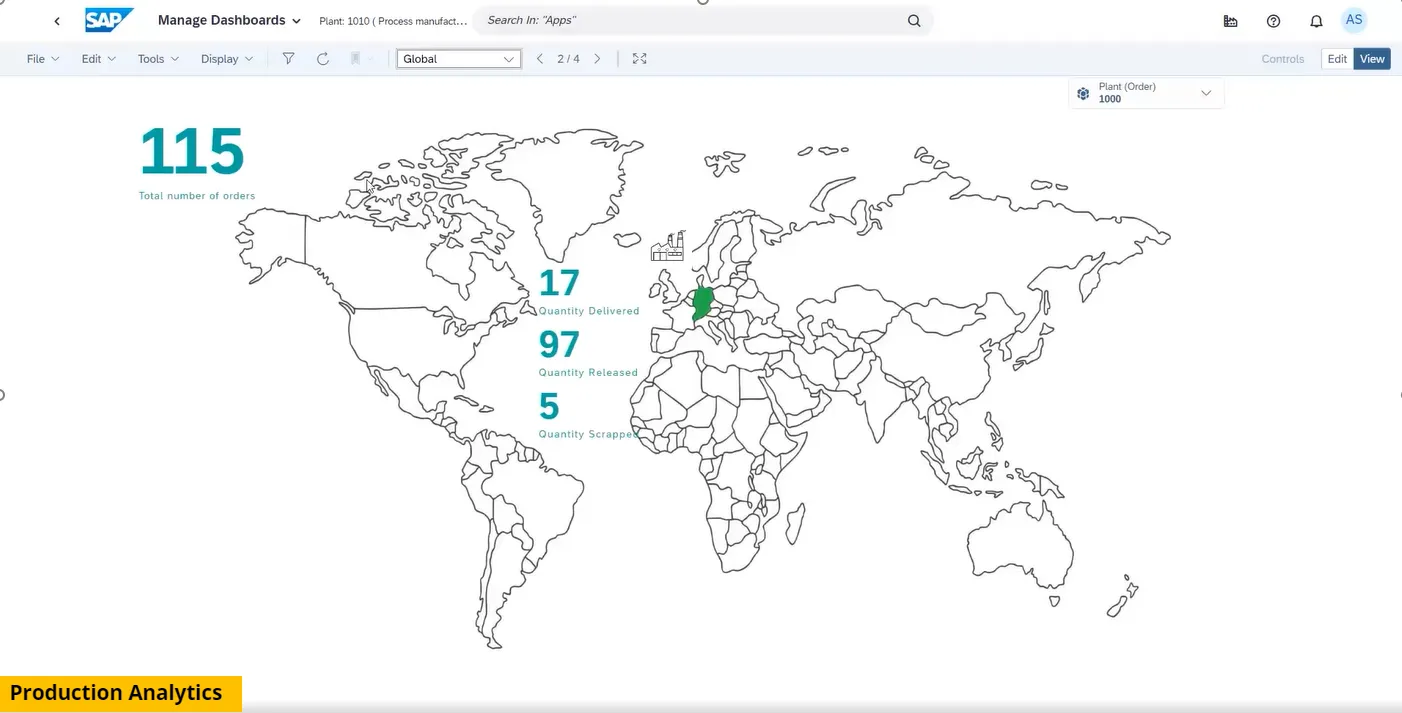

SAP Digital Manufacturing Cloud (SAP DMC), a cloud-based solution, streamlines manufacturing processes by empowering production supervisors and workers to effectively plan and execute production orders. Additionally, SAP DMC enables scenario analysis for process optimization and workload distribution.

Particularly suited for companies with a global presence, SAP DMC offers real-time analytics and valuable business insights at both the branch and company-wide levels.

Core SAP DMC Modules

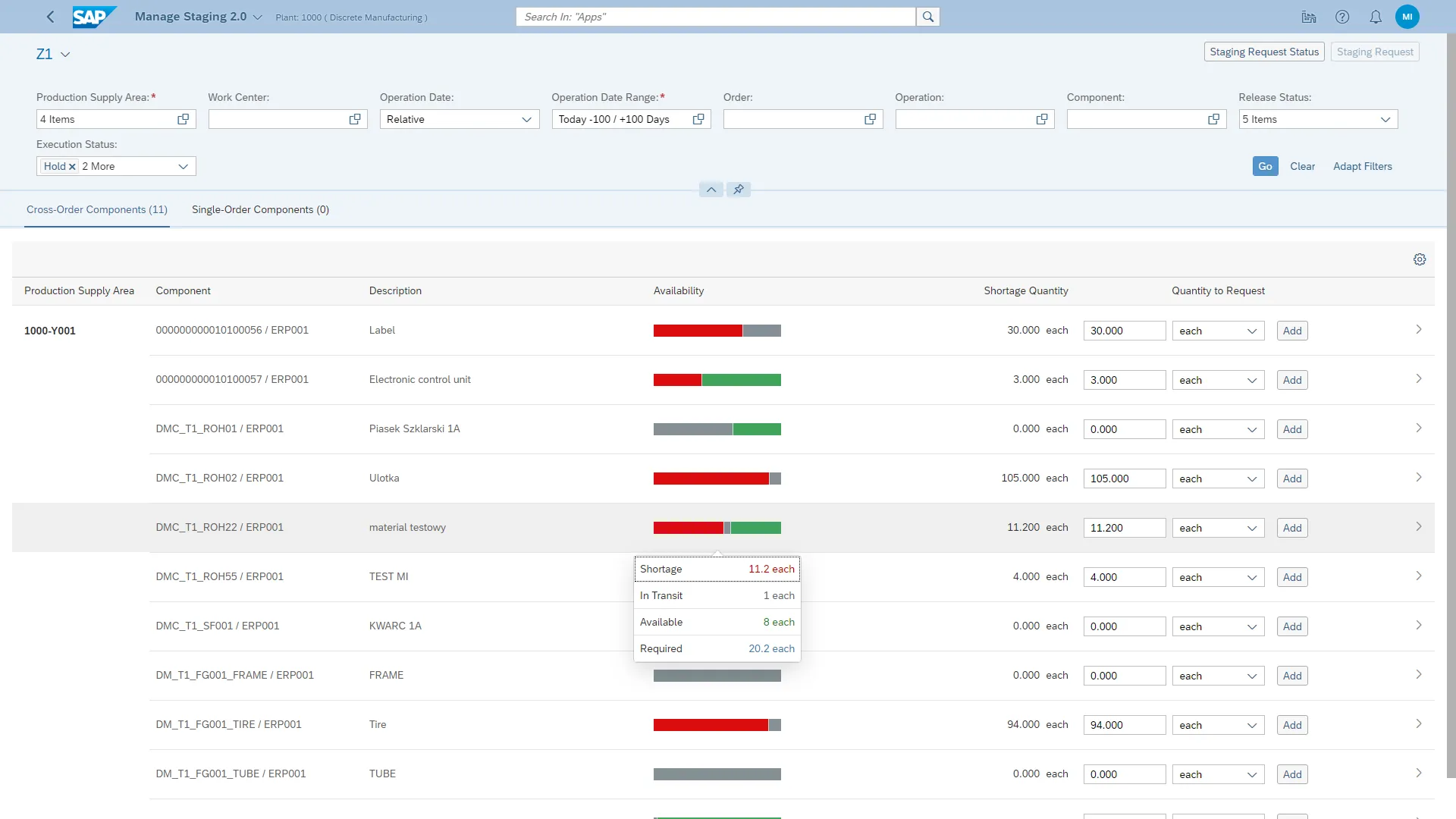

SAP Digital Manufacturing Cloud for Execution

SAP Digital Manufacturing Cloud for Insights

SAP Digital Manufacturing Cloud Resource Orchestration

How SAP DMC Can Benefit Your Business

Improved Performance

Consistent Insights

Faster Production Line Customization

Manufacturing Automation

Effective Execution

Resource Management

What Challenges Does SAP DMC Help to Overcome?

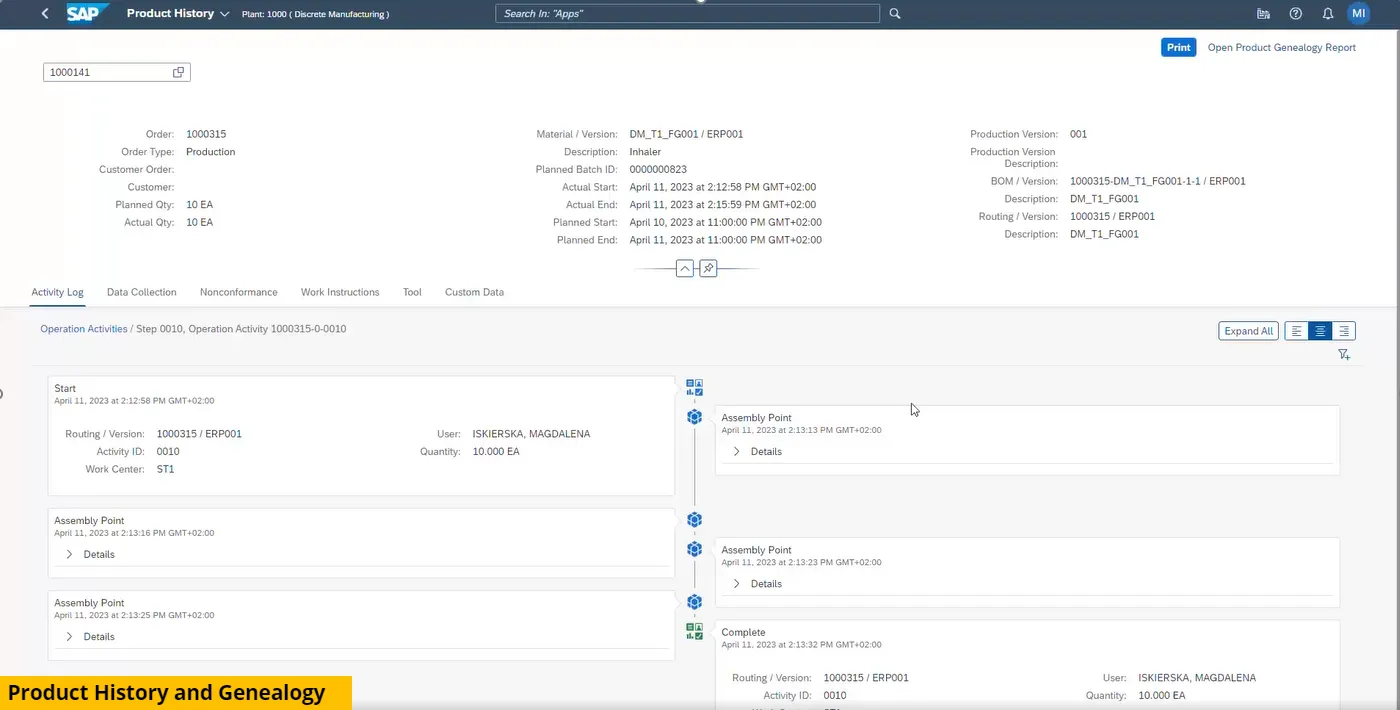

Work in Process Management

SAP DMC provides a graphical routing engine to define, release, manage, and track production flows and order statuses. The solution also gives access to data on bills of material (BOM) and production activity history.

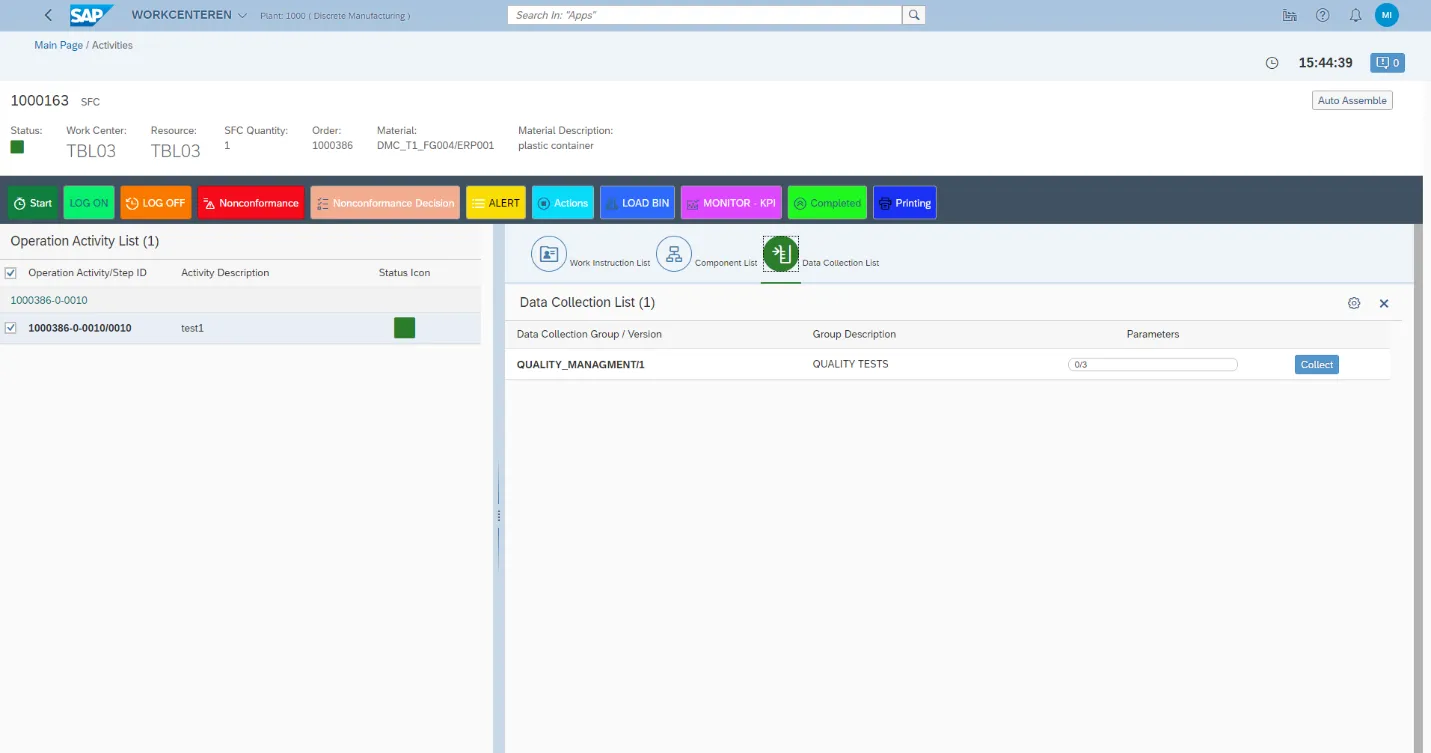

Nonconformance

The system allows for nonconformance recording and status tracking, and uses machine learning to enable visual inspection of manufactured materials to identify production deviations.

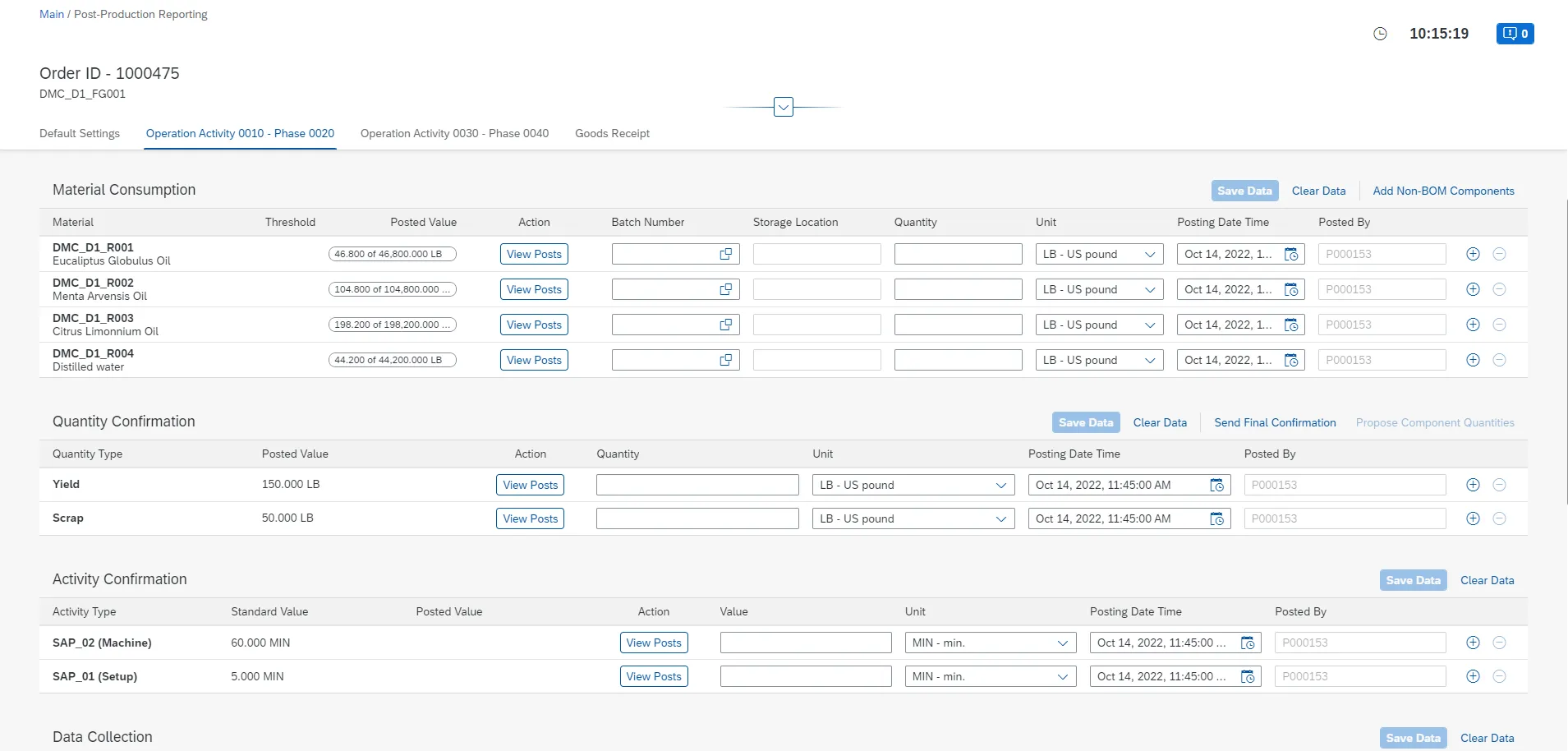

Data Collection and Management

Users can define data collection criteria and types with minimum and maximum limits, and collect data from the production UI. The system also provides warnings when data falls outside of the defined limits. Data can be replicated from on-premise SAP systems, and multiple data models can be created simultaneously. Plant data is accessible from SAP DMC to perform KPI calculations and analytics.

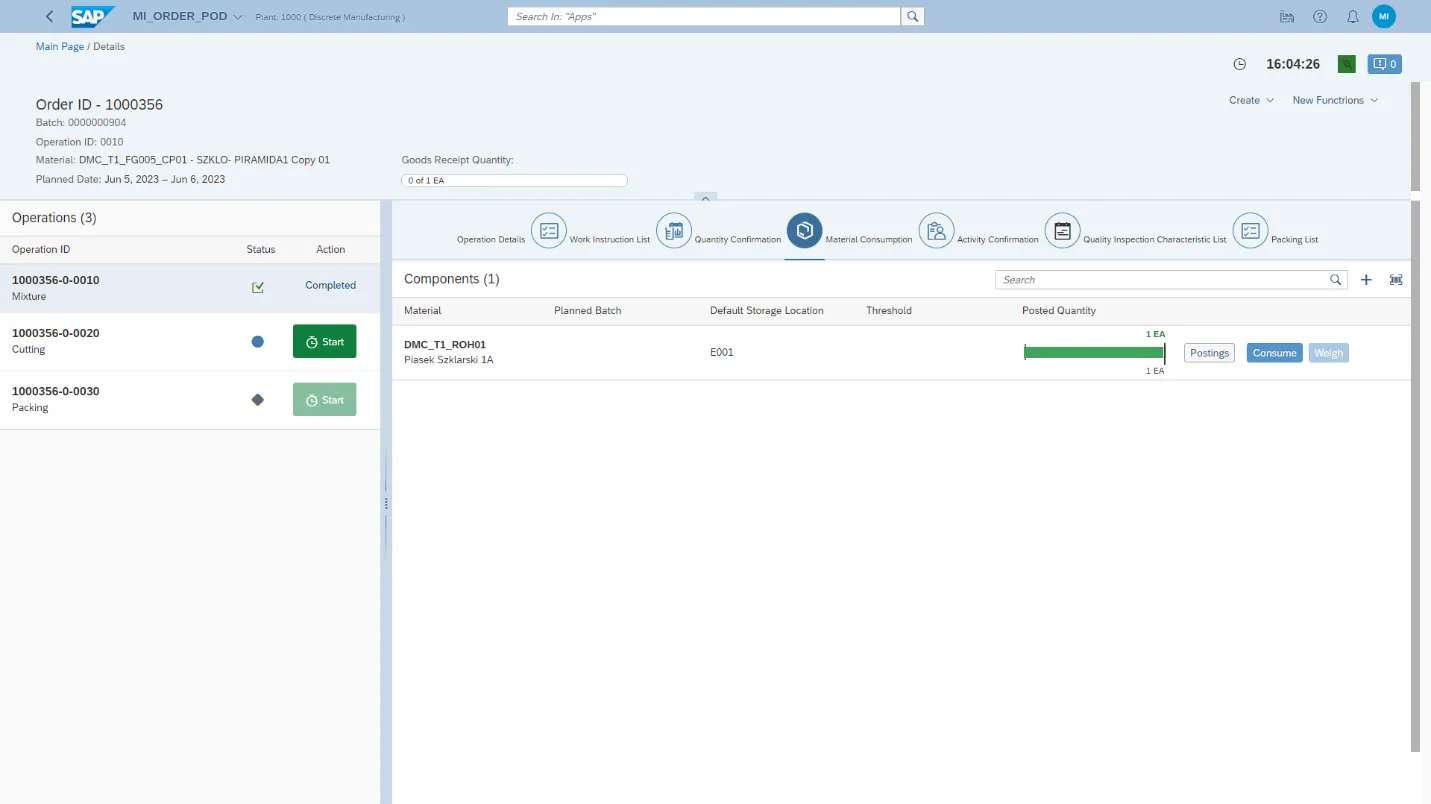

Process Order Execution

Process orders with single and multiple batches can be executed, and SAP DMC integrates with SAP S/4HANA Cloud to replicate key data including process orders, materials, material classifications, work centers, BOMs, batch numbers, recipes, and production versions. Material consumption and scrap can be confirmed, and post-production reporting of order execution data is available.

Monitoring

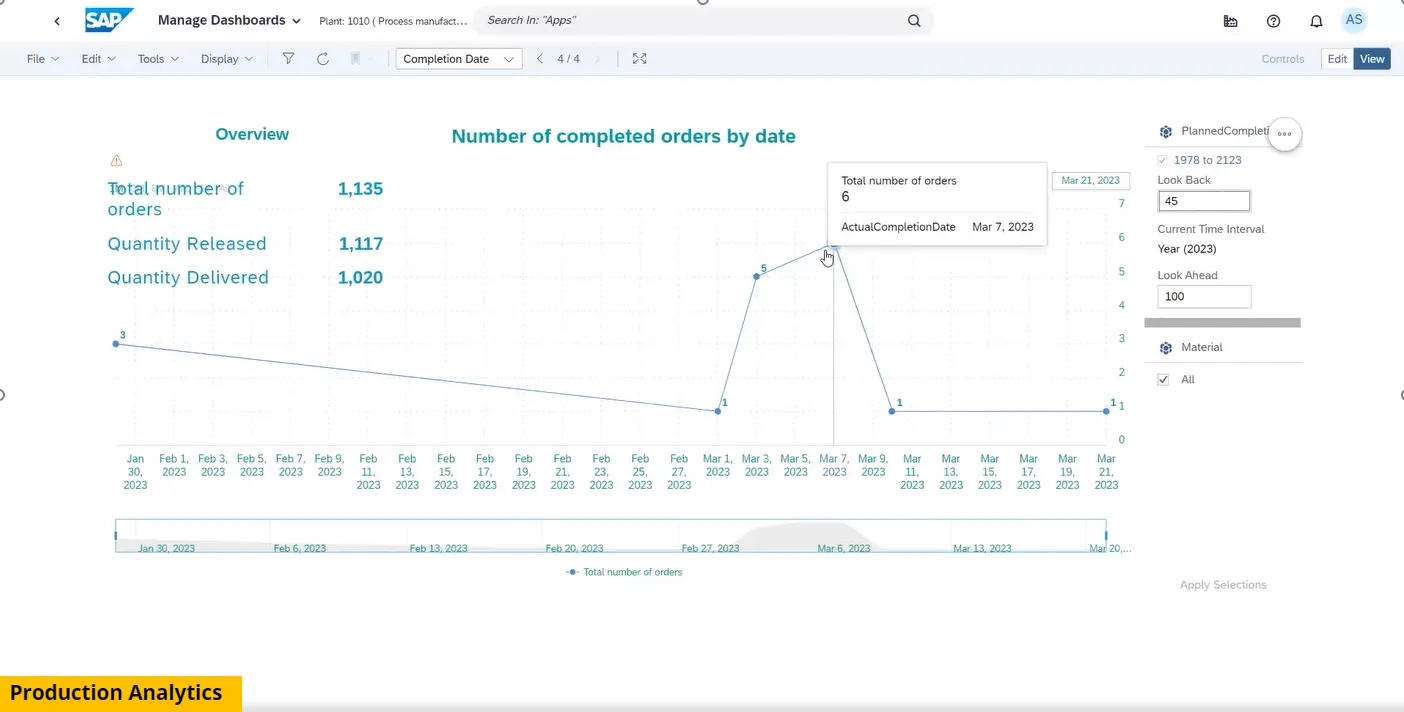

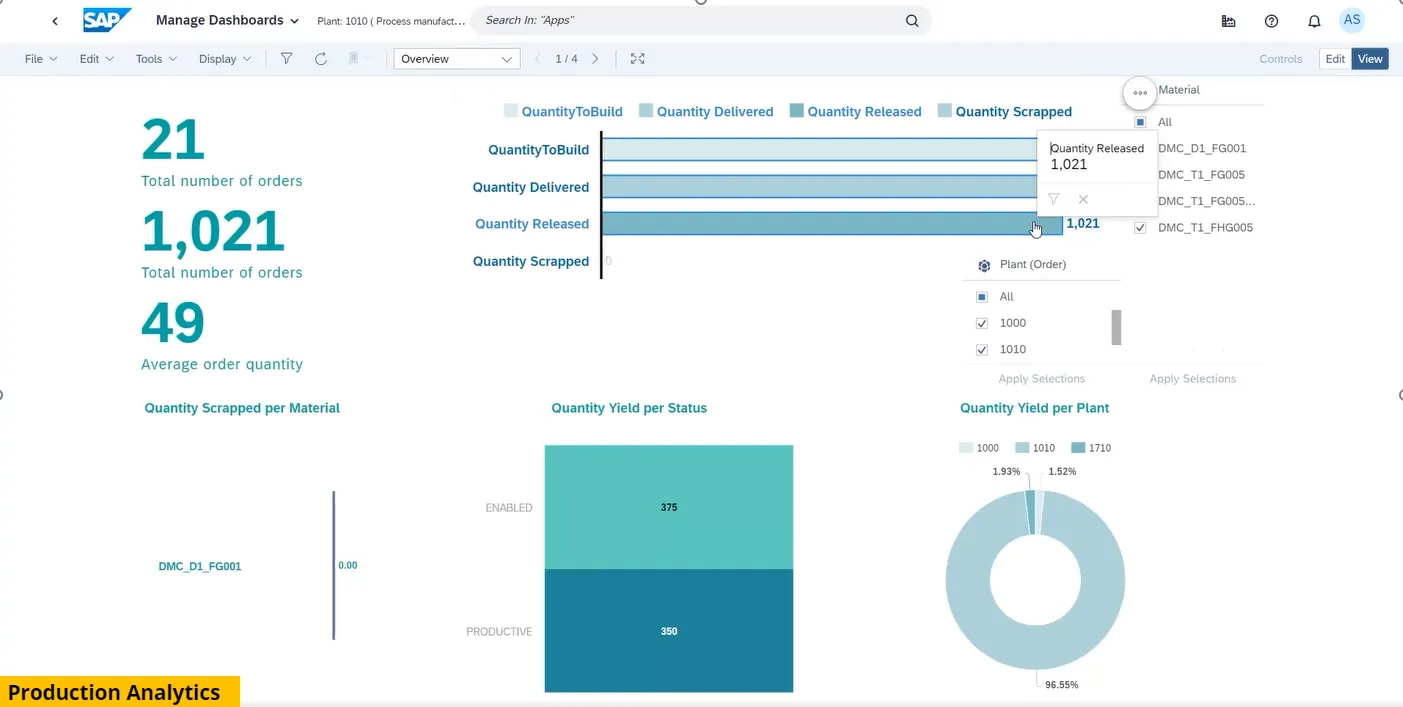

Analytics and Insights

KPI thresholds can be defined across and within plants, and data can be filtered by time range. Near real-time analytics can be performed on standard and custom KPIs, and work orders can be compared and analyzed against planned orders.

How Does SAP DMC Work?

Manufacturing

a large-scale production

Manufacturing/ business

Insights

How We Can Help

Consulting

Implementation

Integration

Support

Application Management

Industries We Serve

Why Choose LeverX as Your SAP Implementation Provider?

Proven track record

Industry experts

SAP partnership

Quality and security track record

Investment in innovation

Flexibility

YOUR PARTNER FOR COMPLETE SAP IMPLEMENTATION IN THE UK

- Determine implementation strategy.

- Propose high-level system architecture.

- Define project implementation methodology.

Discover

- Conduct kick-off meetings to align on documentation, project plan, tracking, and reporting.

- Establish project team and define roles/responsibilities.

Prepare

- Analyze current business processes (AS-IS model).

- Perform fit/gap analysis.

- Demonstrate solution.

- Finalize project scope (TO-BE model).

Explore

- Customize and integrate SAP solutions.

- Develop new functionality (if required).

- Conduct testing.

Realize

- Go-live.

- Transfer data from legacy systems.

- Test and validate roles/authorizations.

- Prepare post-go-live support plan.

- Conduct end-user training.

Deploy

- Resolve outstanding issues.

- Integrate with SAP Solution Manager.

- Provide go-live support.

- Transition users/support team to new software.

Run

Contact Us

What happens next?

-

1

An expert will reach out to you to discuss your specific needs and requirements.

-

2

We'll sign an NDA to ensure any sensitive information is kept secure and confidential.

-

3

We'll work with you to prepare a customized proposal based on the project's scope, timeline, and budget.

years of expertise

projects

professionals

Contact Us

CONTACT US

If you are looking for an SAP Global Strategic Supplier or Technology Partner for your business, fill out the form below, and we will contact you at short notice.