A practical guide to SAP Digital Twins: what they are, how they work in SAP, business value, key use cases, and implementation considerations.

Operations teams are expected to ensure the smooth operation of all equipment, even when the necessary information is scattered. A machine may alarm, but sensor data is stored in one system, maintenance records in another, and production metrics are tracked separately. Problems can be missed until they become expensive. A line shuts down, the supply chain slips, or quality issues trigger rework.

This is where digital twins in the SAP ecosystem can make a significant contribution.

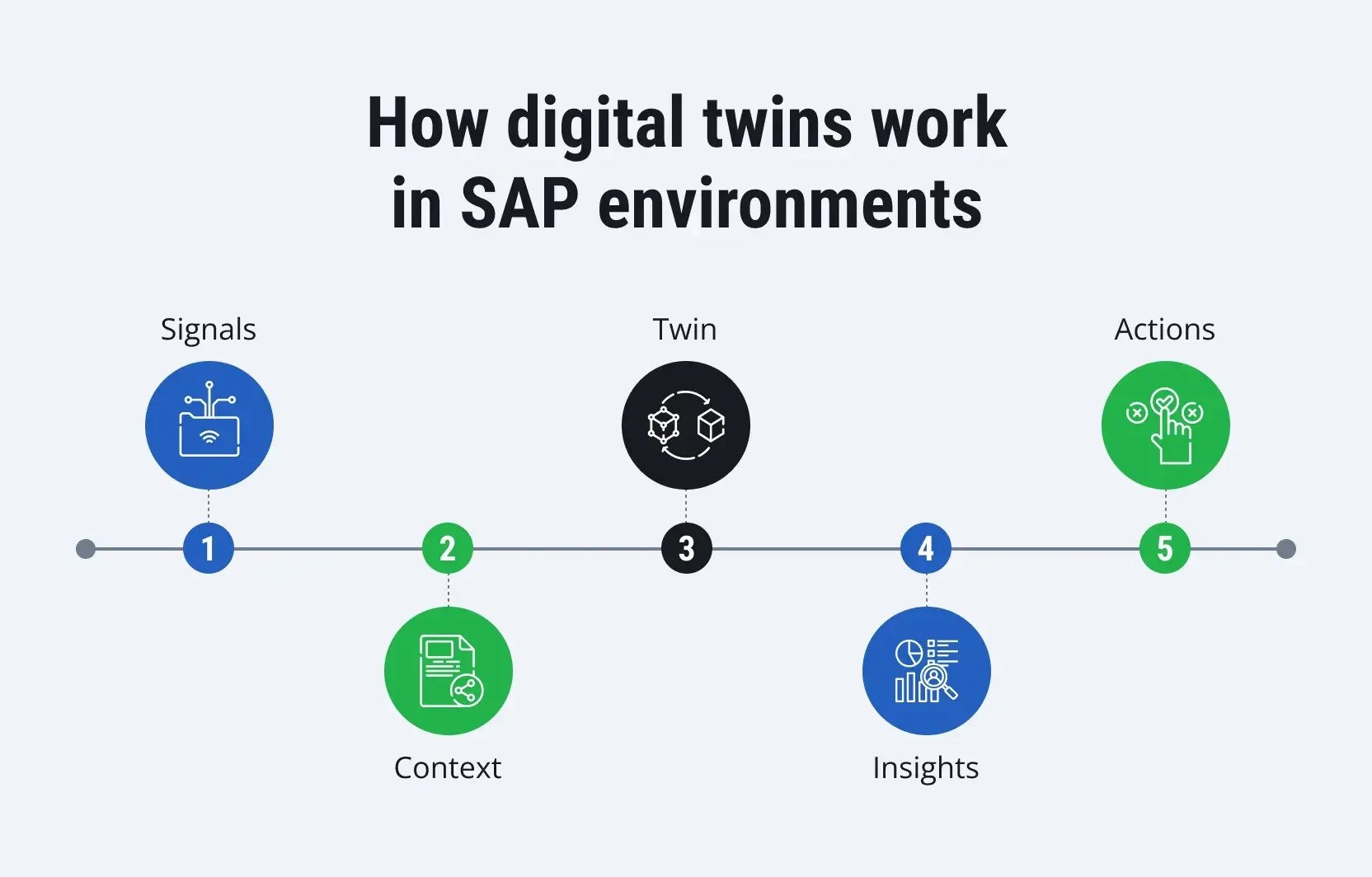

A digital twin is a virtual representation of a physical asset, process, or system that matches real-world conditions using operational and business data. In SAP environments, digital twins help organizations connect operational signals with business processes. This supports continuous monitoring, earlier risk detection, scenario simulation, and faster action through SAP processes.

In this article, we will explain what digital twins are, how SAP supports digital twin use cases, and where they deliver practical value. You will see the key benefits, the most relevant industry scenarios, and the typical steps and challenges involved in implementing digital twins at scale.

What Is a Digital Twin?

A digital twin is a digital counterpart of a real asset, system, or process. It stays connected to how the real thing is operating, updating as new data comes in, so you see its current state and performance, not just the design-time view.

Many people first imagine a CAD drawing or 3D model, but they are quite different. These models are useful for design, training, and documentation, but they remain unchanged even as the actual equipment begins to wear out, exceed tolerance limits, or operate under new loads. A digital twin changes along with the asset. It receives real-time signals, adds business context, and gives teams a clear picture of how something is currently performing.

In SAP environments, that “live view” usually comes from sensor and IoT data combined with enterprise data. You are not just watching signals like temperature, vibration, pressure, throughput, or energy use. You are putting them next to what the business already tracks: work orders, downtime, production status, and quality results. That is what turns a digital twin into something teams can use every day, not another dashboard people check once and forget.

Once those pieces are connected, the twin becomes a practical tool. Teams can track performance as it changes, catch abnormal behavior earlier, and test improvements before applying them in the real operation.

Digital twin vs. digital thread

In SAP terms, the digital thread is the lifecycle backbone. It links information from design and engineering to manufacturing, operations, and service. The digital twin is the current-state model; it updates with live signals and can be used for what-if analysis. The thread is the record and relationships, the twin is the operational view you use to make calls.

Why Digital Twins Matter for Modern Enterprises

For years, companies have relied on assumption-based models and historical averages to make decisions. But in a volatile market, being mostly right is a quick way to lose your competitive advantage. Digital twins are a game-changer, providing a highly accurate, live reflection of your physical assets and processes. It's the difference between viewing a static map and using real-time GPS that accounts for traffic, weather, and road closures.

Here is why they have become mission-critical for modern decision-making:

Reality over assumptions

Digital twins show you how your gear actually runs in the dirt and heat of the real world — with real loads and real wear — not just how it looked on a clean design spec. As live sensor data pours in, you start catching the stuff that standard monitoring usually misses, like a temperature that’s been creeping up for weeks or a cycle time that is stretching out second by second. It’s the shift from crossing your fingers and hoping your assumptions are right to actually knowing what is happening on the floor right now.

The ultimate sandbox

One of the hardest parts of improving operations is the risk. Nobody wants to tweak a process and find out the hard way that it slows production, creates quality issues, or knocks something else out of balance. A digital twin gives you a place to try changes first, before you touch the real equipment. You can test a new warehouse flow, adjust a process parameter, or trial a different operating range, then see what it is likely to do before you roll it out.

Hyper-fast optimization cycles

In an SAP-driven environment, digital twins accelerate the feedback loop between data and action. By integrating with your ERP, they allow for continuous fine-tuning of product designs and supply chain routes. This virtual R&D significantly cuts down the time-to-market and helps teams validate changes before rollout and reduce the risk of unintended impacts.

Core business outcomes

When you get past all the marketing buzz, digital twins really pay off in four ways:

- Reducing downtime: You basically stop flying blind. Instead of waiting for a machine to break, you're tracking wear and tear in a virtual model so you can fix things before the whole line goes down.

- Squeezing value from assets: Most gear isn't actually run at its true sweet spot. By using live data, you can push your equipment based on how it’s actually holding up, rather than just sticking to whatever the manual says.

- Faster root-cause analysis: When something goes wrong, you can trace it back to the moment it started and see what changed. That is a lot better than burning hours on manual troubleshooting while the line sits idle.

- Planning under uncertainty: Instead of planning for the best case, you plan for the week when everything is off schedule. Delays, shortages, route changes. You can see the impact early and choose a response that keeps operations moving.

SAP’s Approach to Digital Twins

SAP does not offer digital twins as a single product you switch on. In most SAP environments, you get digital twin capabilities by connecting the pieces you already use, pulling in operational signals, adding business context, then feeding the result into the workflows teams rely on every day.

Start with operational visibility

On the shop floor, SAP supports digital twin scenarios through tools such as SAP Digital Manufacturing, which helps teams see what is happening in production with near real-time visibility. That typically includes:

- How orders are progressing on the line

- Where throughput starts to drop

- When quality metrics drift

- What events are driving downtime or rework

This layer helps you see what is happening right now and where it is happening.

Add enterprise context so the twin becomes useful

A digital twin is not very helpful if it lives only in operational data. SAP’s strength is tying what is happening in operations to enterprise processes, for example:

- Asset management and maintenance, so a signal can translate into a prioritized inspection or work order

- Quality, so deviations trigger checks and traceability, not just alerts

- Supply chain and planning, so constraints and disruptions can be reflected in plans and commitments

This level helps us understand what this means for cost, risk, and timelines.

Connect data and make it usable at scale

Digital twins depend on a reliable flow of data. In SAP environments, that usually means:

- Connectivity for IoT and telemetry signals coming from equipment, sensors, and edge systems

- Analytics to spot patterns, detect anomalies, and support prediction

- Governance and structure, so data stays consistent across assets, sites, and processes

Without this foundation, teams end up with isolated dashboards instead of something they can run the business on.

How it comes together

SAP connects operational signals from the shop floor or the field with enterprise workflows like maintenance, quality, planning, and supply chain. That is what turns a digital twin from a live view into a tool for decisions and action.

Key Benefits of Digital Twins in SAP Environments for Businesses

In SAP landscapes, digital twin value usually shows up through the systems teams already rely on, manufacturing execution, asset and maintenance management, monitoring, and analytics. You do not buy a digital twin as a separate tool. You build the capability by connecting operational signals with SAP processes, then using that combined view to run operations better.

Here are the benefits companies typically see, and where they most often show up in SAP environments.

Predictive maintenance and fewer failures

When you can see condition changes early, you can plan maintenance before a breakdown forces an emergency stop. In SAP environments, this is often delivered through SAP Asset Performance Management (SAP APM), which now brings together capabilities that previously lived in SAP Predictive Maintenance and Service (SAP PdMS) and SAP Predictive Asset Insights (SAP PAI).

Lower operational costs

Unplanned work is expensive because it disrupts schedules and creates last-minute labor and parts costs. Digital twin scenarios help shift work from reactive to planned. This is closely tied to capabilities typically handled through SAP APM, where performance trends and risk inform maintenance planning.

Real-time monitoring and faster response

A twin is most useful when sensor signals and operational context are visible together, so teams can move quickly from detection to action. In SAP landscapes, this is commonly supported through SAP APM, which brings in the asset health and sensor-based monitoring capabilities that were previously associated with SAP PAI.

Better decision-making through simulation

Teams can compare options before changing a line, a schedule, or a workflow. In manufacturing-heavy SAP setups, this type of improvement work is often supported by SAP Digital Manufacturing, where production visibility and scenario-based optimization can be applied.

Higher throughput and better quality in production

When production execution data is captured in context, it becomes easier to spot bottlenecks and early signs of quality drift, then address the root cause instead of chasing symptoms. This kind of operational visibility is often supported through SAP Manufacturing Execution System (SAP MES) capabilities and broader smart manufacturing practices.

Better collaboration across engineering, operations, and maintenance

Digital twins cut down on the back-and-forth because teams stop debating whose data is right. Engineering details, live operating signals, and maintenance history sit side by side, so it’s easier to hand work off and make calls faster. Tools like SAP Visual Enterprise Generator can still help by turning technical content into visuals that teams can use and share. But the newer digital twin story in SAP is increasingly centered on SAP Enterprise Product Development, where visualization and collaboration are built into the product and engineering workflow.

From Asset Twins to Business Process Twins

Most people first meet digital twins at the equipment level. A twin represents a machine, a production line, or a specific product, and helps answer practical questions like what condition it’s in, what’s changing, and what might fail next. This is the classic digital twin, and it’s where many companies start because the value is easy to see.

But the bigger shift happens when the same idea moves beyond assets and into the way the business runs.

From physical assets to the way work actually happens

A business process twin focuses on how operations behave across systems, teams, and handoffs. Instead of mirroring a pump or a line, it mirrors the flow of work, how orders move, where approvals stall, when exceptions pile up, and what keeps pushing timelines out. It becomes a digital view of how the organization operates, built on real process signals rather than assumptions.

This is often described as a digital twin of an organization, and it’s closely tied to SAP Signavio and process intelligence approaches, where you can map how processes run end to end, then measure performance based on execution data.

Why this matters for business transformation

Asset-level twins help you optimize performance locally. Process-level twins help you remove friction across the entire value chain.

What companies get from this shift:

- Process transparency: You see where time and cost disappear, such as recurring delays, rework loops, manual approvals, or system-driven bottlenecks.

- Safer improvements: Instead of changing a workflow and hoping it works, you can model the impact first and compare scenarios before rolling anything out.

- A stronger foundation for transformation programs: Process transformation often fails when teams rely on workshops and how-it-should-work diagrams. A process twin gives you evidence from execution data and supports continuous improvement based on what is actually happening across systems.

In other words, asset twins help you run operations better. Business process twins help you change how the business runs, with less guesswork and fewer side effects.

Main Use Cases and Industries

Digital twins tend to deliver the most value where operations are complex, assets are expensive, and small issues quickly turn into downtime, waste, or missed commitments. The use cases below are the ones enterprises most often prioritize because the impact is easy to measure and scale.

| Industry | Typical digital twin focus | What teams use it for | Common outcomes |

| Manufacturing | Virtual factory, production line, critical equipment | Improve throughput, energy use, and quality, troubleshoot faster, test production changes before rollout | More stable output, fewer surprises during changes, and earlier detection of performance and quality drift |

| Logistics and supply chain | Shipment and route visibility, network constraints, scenario modeling | Track what is happening now, test disruption scenarios such as delays, lane closures, capacity drops, and demand spikes | Faster disruption response, stronger service levels, more resilient planning |

| Energy and utilities | High-value rotating equipment, condition monitoring, and maintenance risk | Reduce outages by catching degradation early, scheduling condition-based maintenance, and extending asset life | Fewer unplanned outages, better maintenance timing, lower operational risk |

| Process industries and chemicals | Process stability, equipment trains, safety-critical monitoring | Detect drift early, stay within safe limits, evaluate parameter changes before applying them | Fewer quality deviations, improved stability, stronger safety posture |

| Facilities and large sites | Building systems, energy use, space, and flow | Simulate layouts and workflows, optimize resource use, and monitor critical infrastructure systems | Better space utilization, reduced energy waste, and smoother site operations |

The strongest digital twin use cases share one thing — they turn messy operational reality into something teams can see, measure, and act on. Most organizations start with a single high-impact area, such as a critical asset group or a production line, then expand once the data foundation and operating model are in place.

A Step-by-Step Approach to Digital Twins in SAP

Digital twin work can sound like a big transformation program, but it does not have to start that way. The easiest path is to treat it like a staged build. Start small, prove value, then expand once the data and operating model are stable.

Define the scope and success metrics

Pick one clear target and keep it practical:

- A critical asset (high downtime cost, high failure risk)

- A production line or process step that limits throughput

- A business process with repeated delays and exceptions

Then lock in a short set of KPIs, for example, uptime, mean time to repair, scrap rate, cycle time, energy use, or schedule adherence.

Connect the data sources

A twin is only as useful as the data behind it. In SAP landscapes, this usually means pulling from two layers:

- Operational signals like sensors, Internet of Things telemetry, and machine data

- Enterprise events like manufacturing execution, maintenance history, quality records, and planning updates

In many setups, SAP Business Technology Platform acts as the bridge between factory-floor sensors and shop-floor systems (operations technology) and the enterprise applications that run planning and execution (information technology).

Build the data model and context

This is the step that keeps the twin from becoming just another dashboard.

You connect the signals to the business structure:

- Asset hierarchy and locations

- Product and work center relationships

- Master data that links events to the right equipment, line, or process

When the relationships are clean, teams stop hunting for meaning and start using the twin to make decisions.

Set up monitoring and alerting

Start with basic monitoring that matches real operational pain:

- Thresholds that flag abnormal behavior

- Alerts tied to meaningful conditions, not noise

- Rules that reflect how teams actually respond

A good first target is early-warning detection that reduces firefighting.

Add analytics and prediction

Once monitoring is stable, you can move from “what is happening” to “what will happen next”:

- Failure pattern detection

- Anomaly trends over time

- Optimization recommendations, such as maintenance timing or operating adjustments

This is where the twin begins to support planning, not just response.

Connect insights to SAP workflows

This is the difference between insight and impact.

The twin should drive action through the processes people already use:

- Create or prioritize maintenance orders

- Trigger quality inspections or checks

- Adjust production and planning decisions based on constraints

If insights do not translate into workflow, they usually get ignored.

Build closed-loop execution in SAP S/4HANA

To get real outcomes, especially reduced downtime, the loop has to close inside the system of record. In practice, that means the twin must be able to trigger action in SAP S/4HANA, for example, by creating a service notification or a maintenance work order, or at least pre-populating one for fast approval. Without that step, insights stay stuck in dashboards, and the impact on downtime is hard to realize consistently.

After the pilot works, scaling is mostly about consistency:

- Reusable templates for similar assets and lines

- Governance around data quality and ownership

- Rollout plans by site, plant, or region

The goal is to keep the twin reliable everywhere, not just in one perfect location.

Scale across assets, lines, and sites

After the pilot works, scaling is mostly about consistency:

- Reusable templates for similar assets and lines

- Governance around data quality and ownership

- Rollout plans by site, plant, or region

The goal is to keep the twin reliable everywhere, not just in one perfect location.

Common Challenges and How To Avoid Them

Digital twins only work when the foundation is solid. When they flop, it’s usually because the data is a mess, nobody knows who actually owns the process, or the team tried to go too big too fast.

Here is a look at the most common ways these projects fail and how to actually fix them.

Data quality and master data gaps

When equipment IDs don’t match across systems, asset hierarchies are a mess, or key events are missing, the twin starts giving you a fuzzy picture. People notice, confidence drops, and the tool gets ignored.

How to avoid it: keep the first scope small, clean up the master data for that specific area, and agree on naming and structure upfront. Treat data cleanup as part of the rollout, not something to fix later.

Integration complexity and OT/IT alignment

Digital twins sit right at the intersection of operations technology and enterprise systems. That means you are connecting different owners, different priorities, and often different standards.

How to avoid it: lock down the data requirements early, what you need, how often it updates, and which system is the source of truth. Start with one small integration you can trust, run it end to end, then expand only after it’s solid.

Sensor readiness

Not every asset is instrumented, and even when sensors exist, the data may be noisy, incomplete, or not collected at the right frequency.

How to avoid it: pick assets where signals already exist and where downtime is expensive. For the rest, plan sensor rollout as a separate workstream instead of blocking the full program.

Cost and ROI uncertainty

Digital twins can look like a big investment if the value is framed too broadly. Trying to justify an enterprise twin upfront is a tough sell.

How to avoid it: pick one high-impact use case to start, set clear KPIs, and treat phase one as a "proof of value" step. Once you’ve got actual results on the table, scaling the project becomes a much easier conversation.

Ownership and long-term maintenance

A twin is not a one-time implementation. It needs upkeep, data checks, model changes, and clear accountability. Without an owner, it gradually falls into decay.

How to avoid it: treat the twin like a real operational system, not a one-time project. Set ownership, define responsibilities, and agree on a change process. Shared input works, but keep decision rights with one team.

Future Outlook and Business Opportunities

Digital twins are moving from a nice-to-have innovation to a capability that sits at the center of modern operations. For many enterprises, they are becoming part of the digital transformation toolkit, not because they look impressive, but because they make day-to-day execution more predictable and easier to improve.

From monitoring to optimization, and beyond

Most companies start with visibility. They want a clearer picture of what is happening right now. The next step is optimization, using the twin to compare options, tune performance, and prevent problems instead of reacting to them. Over time, the goal shifts again, toward decision loops where the system can recommend actions automatically, and in some cases trigger them through workflows with minimal manual effort.

This is where digital twins stop being a dashboard layer and start becoming an operating advantage.

Where the business opportunities are heading

As the capability matures, digital twins open up opportunities that go beyond maintenance and production tracking.

New service models

Instead of selling products and spare parts, companies can offer outcomes, such as guaranteed uptime or performance-based maintenance. A reliable twin makes that possible because it supports transparency, prediction, and service planning.

Faster commissioning and ramp-up

Bringing a new line or site online is expensive, and early mistakes are hard to unwind. Digital twins help teams test configurations and operating ranges earlier, so ramp-up is smoother and less dependent on trial and error.

More resilient operations

When something goes wrong — a delivery delay, a line breakdown, an unexpected outage — the companies that recover fastest are those that can run through multiple scenarios and choose the one that causes the least damage. Teams recover faster when scenario analysis is already part of routine planning, not something invented during a crisis.

Efficiency and sustainability improvements

A twin can also highlight where energy is being wasted, where processes are running outside optimal ranges, or where rework and scrap can be reduced. The value here is practical, lower consumption and fewer losses, not vague promises.

The bigger picture is simple. Digital twins help companies move faster without gambling on changes. They shorten the distance between what is happening in operations and what the business does about it, which is exactly where competitive advantage is built.

Conclusion

Digital twins in SAP environments help bridge the gap between what operations departments are doing and what the business is doing next. When real-time signals are linked to the SAP context, problems can be identified early, multiple "what if" scenarios can be tested before making changes, and the resulting data can be translated into action through maintenance, quality control, and planning.

The smartest starting point is one use case where the payoff is obvious. Choose a critical asset group, a line that limits output, or a process that keeps causing delays. Set a handful of KPIs, then use the pilot to prove the impact with real numbers.

The next step is simple. Analyze the existing data, identify any gaps, and choose a pilot project that you can support from start to finish. Once it's working, scaling will be a matter of iteration, not rethinking.

How useful was this article?

Thanks for your feedback!

.jpg)