We explain how SAP solutions can help manufacturing companies based on our customer's success stories.

SAP for the Manufacturing Industry: 5 Real-Life Success Stories

The events of recent years have become a tipping point for the manufacturing industry, proving that if companies want to stay competitive, they can’t return to traditional approaches to production and supply chains.

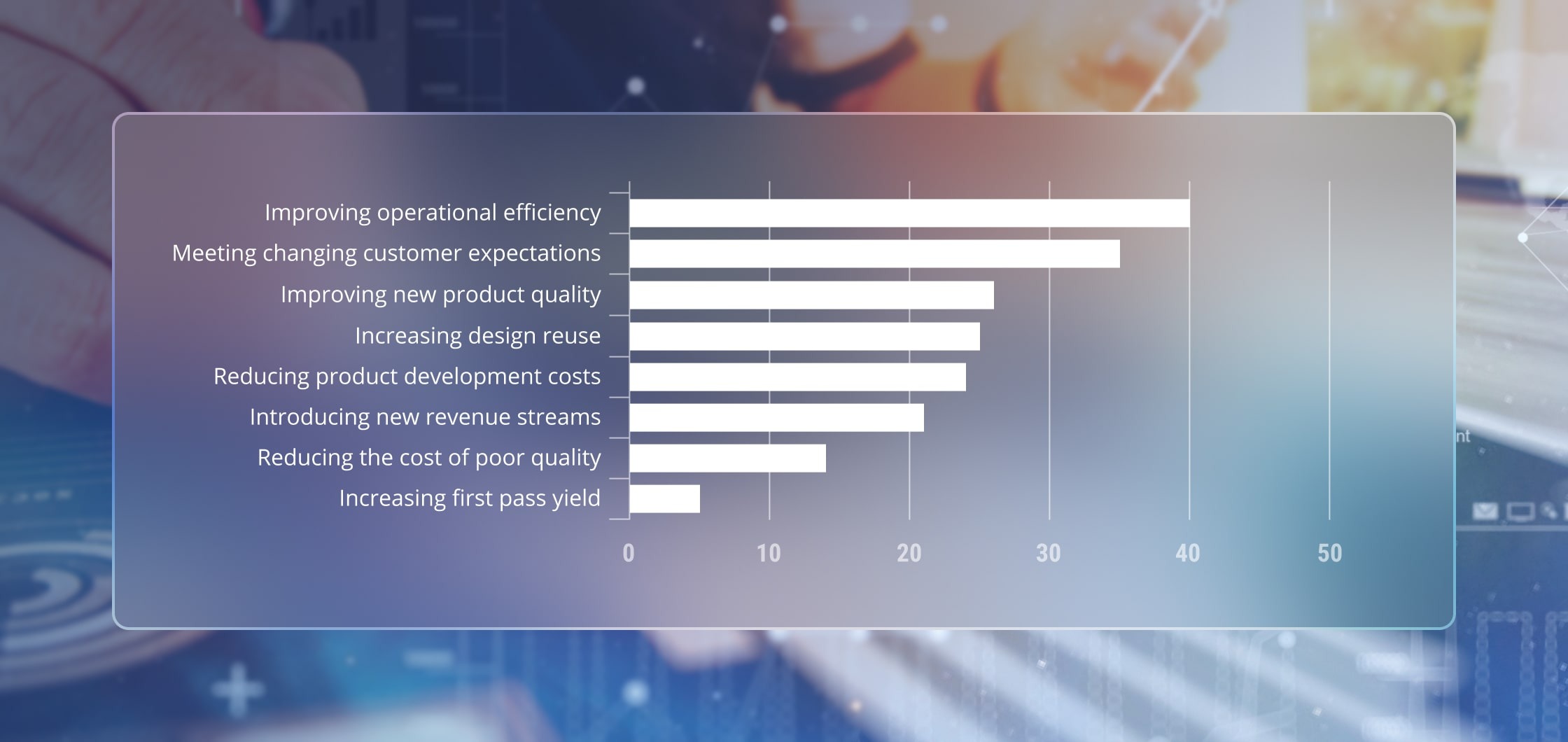

According to a Forbes report, 95% of manufacturing companies were significantly impacted by global events. Eighty-nine percent were concerned about their current supply chains; quality issues caused cost overruns for 81% of respondents. Among other issues, they also mentioned challenging sourcing and onboarding new vendors, quality control management, and slow feedback loops with manufacturing partners that add time to market.

It led to increased investments in companies’ digital transformation (91%). Ninety-five percent of them agree that digital transformation of manufacturing is essential to their company’s future success.

Source: FinanceOnline

How Can SAP Help?

Nowadays, SAP offers a wide range of software solutions to accelerate the time to market, enhance production efficiencies, and reduce operational costs in the manufacturing companies.

Among other benefits, these solutions cover crucial manufacturing processes and can help businesses achieve the following:

Implementing SAP manufacturing solutions helps companies build an intelligent factory aligned with the Industry 4.0 principles based on Big Data collection, processing, and used to execute manufacturing processes without human input.

Let’s consider how it works using the LeverX projects as examples.

SAP PLM Migration for a Manufacturer of Dispensed Beverage Equipment

SAP Product Lifecycle Management (SAP PLM) enables companies to manage a product's lifecycle at each stage, from initial design to end of life.

SAP PLM ensures the following:

- Data synchronization across the company

- Constant updates of engineering changes

- Quick access to data for everyone involved in a project

- Resource optimization

- Reduced time to market

- Minimization of downtimes and inefficiencies of processes, etc.

Why did the customer approach us?

The customer faced internal challenges resulting from product design changes. When the client requested enhancements, they employed a slow process to envision and design new products for prototype and production.

How did we help?

Our SAP PLM migration project was launched in 2009 with the selection of the SAP ERP platform, based on SAP providing a robust and fully integrated PLM module. The project consisted of three main phases:

- Creating an initial single source for a document management system and building an efficient document change process. This provided versioning, revisions, history, and complete linkage between documentation and SAP master data.

- Removing out-of-date project management software and migrating to SAP Enterprise Portfolio & Project Management. The PPM solution afforded the ability to create projects, assign resources, track project time, and report and manage resource PTO time.

- Expanding portfolio and project management. This phase of the project was ongoing and emphasized expanded PPM capabilities, improving project resource management, project cost management, robust project reporting, and PPM workflow.

Results

R&D and Engineering Modernization Using SAP ECTR

SAP Engineering Control Center (SAP ECTR) ensures seamless integration of external CAD solutions with SAP PLM, allowing you to view all CAD data and automate the creation of documents, materials, and specifications in the SAP system based on CAD files.

SAP ECTR's key advantage is transferring data created in major CAD systems into SAP for the successful planning, procurement, production, sales, and other processes without additional integrations.

Why did the customer approach us?

The client, a consumer goods manufacturer in the USA, was using an outdated CAD integration toolset for managing R&D/Engineering data and integrating with SAP. Due to its complexity and outdated nature, the system was limited to specific R&D data only.

This resulted in the following:

- User interface, user experience, and efficiency issues

- Time consumption

- Missing critical functionality

- Challenging product lifecycle management

How did we help?

We deployed the SAP ECTR interface to leverage a single, integrated platform for R&D data, enabling a view of all product development information. This included data from planning, purchasing, manufacturing, engineering, and quality teams. The main CAD tool in use is SOLIDWORKS, which is directly integrated via ECTR.

SAP ECTR provided the R&D/Engineering teams with an engineering-friendly workspace to design, engineer, and innovate while connecting the design and engineering data with the business data in SAP.

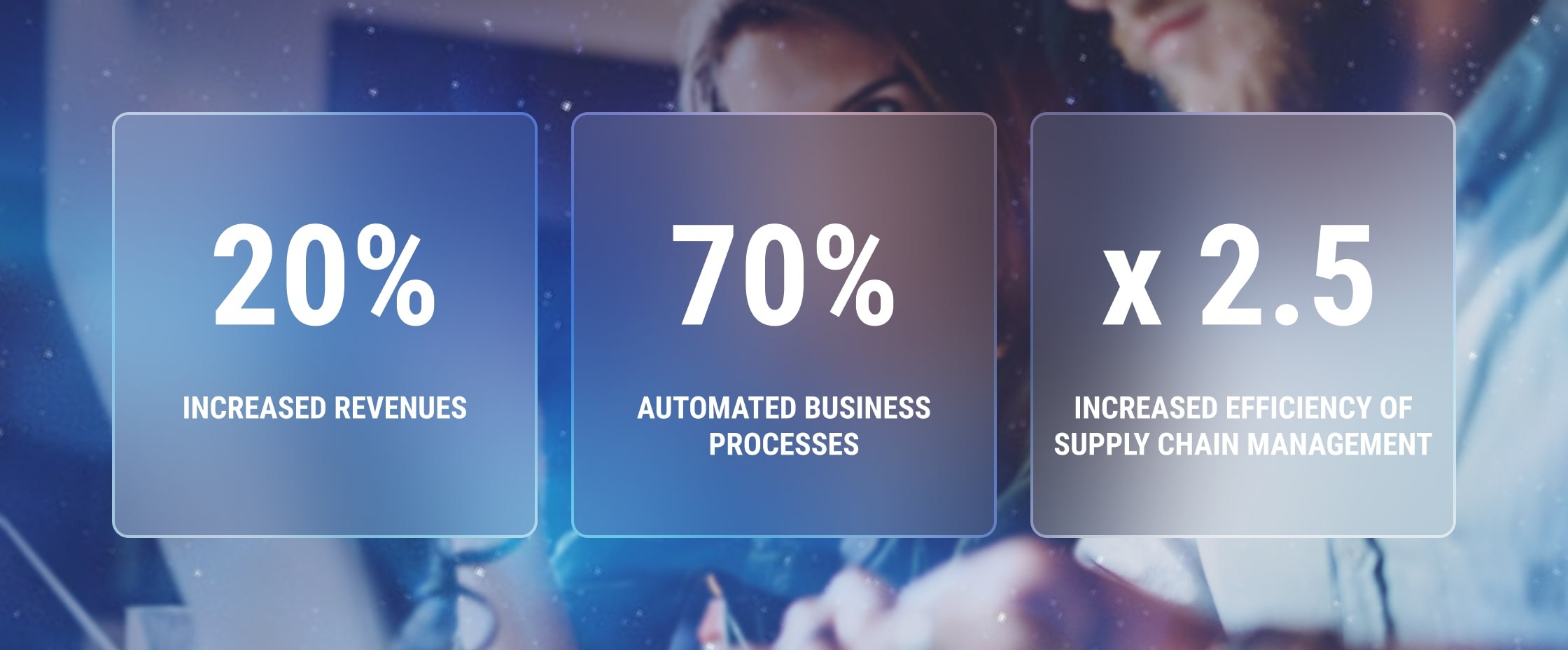

Results

SAP Implementations for Enable Injections

Enable Injections develops and manufactures discreet body-worn delivery devices that allow patients to self-administer high-volume and/or high-viscosity therapeutics. Our joint project involved, among other things, the implementation of SAP PLM and SAP ECTR.

Why did the customer approach us?

Enable Injections was using manual paper processes, which were time-consuming and did not allow for quick scalability. Another business challenge was the necessity to secure expensive drugs received from the company’s partners by a best practice ERP system to ensure their traceability through the entire lifecycle.

In addition, the company was challenged due to many functional departments using a silo approach, creating communication delays and barriers to real-time information.

How did we help?

Since 2018, LeverX and Enable Injections have been partners. Over the last five years, we have gone through four project phases:

- Implementing Financial module

- Implementing Material Management, Sales and Distribution, Productions Planning, Financial Controlling, and Document Management

- Implementing Product Lifecycle Management (Part 1), Plant Maintenance, Quality Management

- Implementing Product Lifecycle Management (Part 2)

Results

SAP PLM Migration for a Medical Device Manufacturer

In this case, our client was a leading developer and manufacturer of light-based aesthetic and medical treatment systems. The company produces, develops, and manufactures various leading treatment applications for hair removal, skin revitalization, scar reduction, gynecological health, body contouring, and more.

Why did the customer approach us?

The company operates in a heavily regulated industry that requires strict control processes and data management. Therefore, our customer required an advanced PLM system that could ensure meeting these requirements.

How did we help?

LeverX assisted with data migration from multiple legacy systems and integration into SAP PLM. We also configured the PLM system to ensure its flexibility to accommodate the unique business processes required by the government.

Our specialists implemented core PLM which included: data management processes for materials, Bill of Materials (BOM), document and engineering changes, material classification, and BOM redlining.

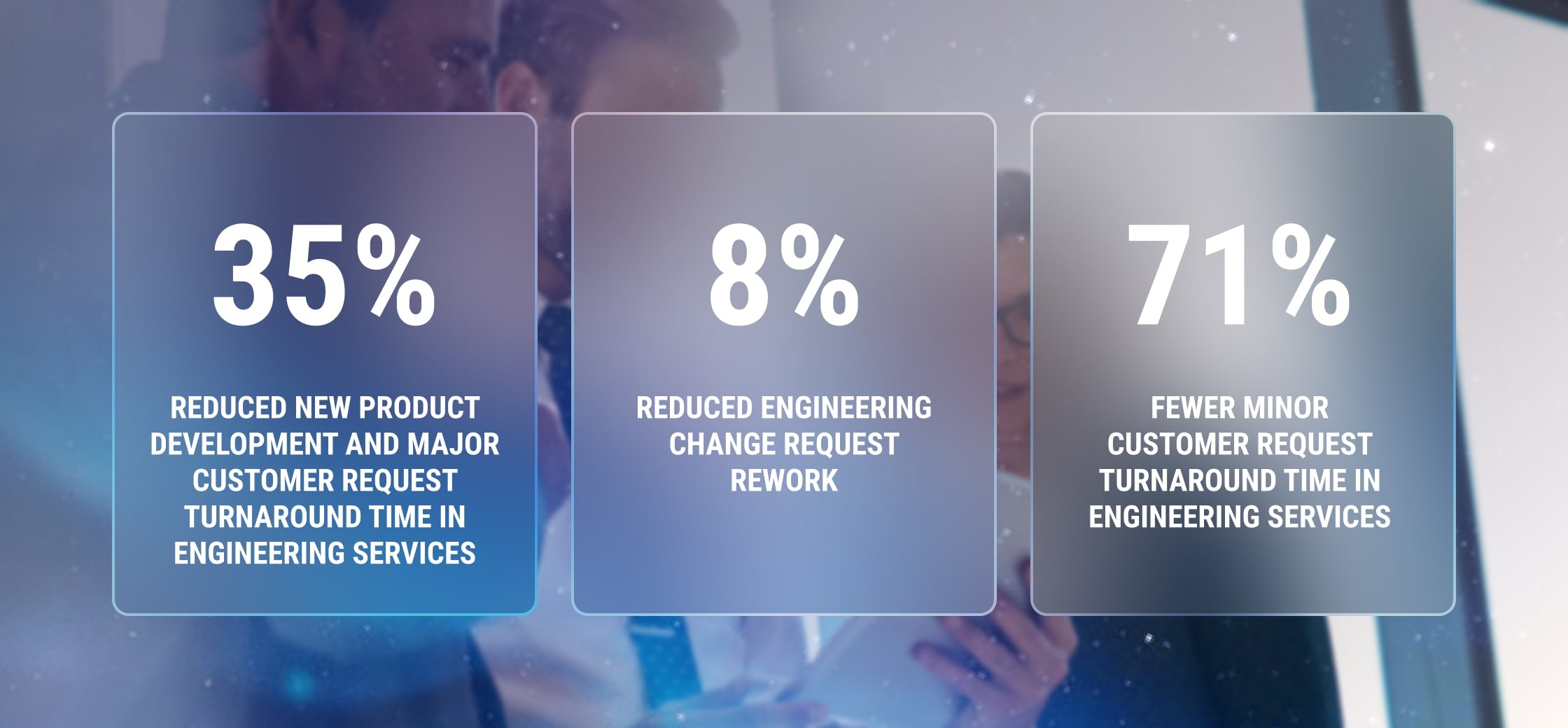

Results

SAP Yard Logistics Implementation for Improved Floor Transport Load Planning

SAP Yard Logistics (SAP YL) is a dedicated yard management solution used to facilitate the planning and execution of all yard operations. This solution offers the following features:

- Monitoring yard functionality and visualizing status information

- Accelerating the gate processes using advanced data analytics

- Reducing waiting times

- Recording inspection-related information and managing exceptions

- Automatically determining loading position, etc.

Why did the customer approach us?

A large truck manufacturer couldn’t solve incidents rapidly (spare parts aren’t available for shipping, the forklift is out of order, etc.), had a time-consuming process to prepare shipping manifests, and lacked transparency in monitoring the movement of forklifts.

How did we help?

After analyzing the client's internal workflow processes, our team implemented, configured, customized the SAP Yard Logistics solution, and integrated it with the following SAP products and third-party software:

- SAP Enterprise Resource Planning (SAP ERP)

- SAP Transportation Management (SAP TM)

- Third-party GPS tracking solution

Results

The Bottom Line

SAP PLM, SAP ECTR, and SAP YL are only a part of SAP manufacturing solutions. The LeverX experts also name SAP S/4HANA, SAP DMC, SAP MES, and SAP MRS in this list.

If you want to learn more about all the manufacturing solutions provided by SAP or are still determining which will meet your business needs, contact us! We will be happy to help you!

How useful was this article?

Thanks for your feedback!

.webp)

.webp)

.webp)