Before investing in supply chain automation, you need to understand the state and future of the market and have a clear understanding of each stage of the digital transformation process and possible pitfalls. This article may help you decide whether to follow the digital trend.

Supply Chain Automation: A Passing Trend or a Harsh Necessity?

Today's supply chains are evolving rapidly due to the increasing complexity of world trade. Because customer requirements constantly change in this highly competitive, volatile environment, a one-size-fits-all approach is inefficient and can be confusing.

But what is actually behind supply chain automation? What will the logistics of the future look like? These are questions that every industry must ask themselves. The further development of supply chain management is inevitably influenced and changed by digital transformation. Let’s discuss this topic and find an answer together.

What is Supply Chain Automation?

Many companies do not clearly understand what is going on through their entire supply chain, especially when they are geographically distributed or remotely controlled. However, many of the worst potential risks and supply chain disruptions can remain hidden within these tiers, and the ability to communicate in real time with all mechanical assets throughout supply chain operations is higher than ever before.

Supply chain automation is about implementing automated solutions at stages such as production, warehousing, or transportation of goods. The goal is to eliminate cost overruns in the various operations. Automation can refer to the following areas of production:

- Processing operations

- Conveying processes

- Handling and storage operations

- Developments

- Production planning

- Control operations

In automated production, all processes, like the processing, monitoring, and controlling tools and systems, are implemented mechanically or electronically using digital systems.

Manual work is broken down into partially or fully automated processes. Through the intelligent action of a digital system, supply chain managers can better support the work processes of different production steps, increasing employee productivity and profitability.

How Automation Drives Digital Transformation

End-to-end automation of business processes is a cornerstone for digital business transformation because the traditional linear supply chain is only as strong as its weakest link. Traditional supply chains often contain gaps and silos where logistics managers lose sight of their partners and the goods and materials for which they are responsible. However, when supply chains are connected — when everyone from the raw material supplier to the delivery driver is part of the same network — the opacity is removed.

The shift to automation is becoming more prevalent as many modern logistics setups are now automating their operations. According to an analysis by Gartner, supply chains will become autonomous faster than expected; the supply chain will evolve from automation to autonomy in the next decade.

“Most CSCOs (Chief Supply Chain Officers) in companies that are part of the global supply chain agree that the most advanced global supply chains will see hyper-automation in the next ten years,” said Pierfrancesco Manenti, VP Analyst on Gartner's Supply Chain Strategy Team and author of the report.

Instead of a serial view of the links in a linear supply chain, a digitized, cloud-based system views the supply chain as a connected network. This “network view” of the supply chain makes it easier for teams to collaborate and helps mitigate risks once they present themselves. The interconnectedness of a cloud-based system coupled with the power of artificial intelligence (AI) and machine learning means that the more data flowing in and out of the supply chain network, the more accurate demand forecasting, process automation, and coordination the multitude of moving parts that make up the operation.

Top 5 Benefits of Supply Chain Automation

Improved efficiency

Supply chain automation can streamline logistics operations, resulting in improved efficiency. Automated processes such as order processing, inventory management, and transportation planning can eliminate manual errors and reduce the time required to complete tasks. This efficiency leads to faster order fulfillment, reduced lead times, and overall smoother logistics operations.

Enhanced visibility

Automation technologies provide real-time visibility into the supply chain, allowing logistics managers to track inventory, monitor shipments, and identify potential bottlenecks or delays. With improved visibility, companies can proactively address issues, optimize routes, and make data-driven decisions to ensure efficient and reliable logistics operations.

Cost savings

Automation can help reduce costs throughout the logistics process. By eliminating manual data entry and paper-based processes, companies can minimize administrative errors and reduce labor costs. Automated inventory management can optimize stock levels, preventing overstocking or stockouts, leading to significant cost savings. Additionally, automation can help optimize transportation routes, reduce fuel consumption, and improve vehicle utilization to lower transportation costs.

Increased accuracy

Supply chain automation minimizes the risk of human error by replacing manual processes with automated systems. Automated order processing and data entry reduce the chances of errors such as incorrect shipments or inaccurate invoicing. This increased accuracy helps maintain customer satisfaction, reduces the need for costly returns or rework, and improves overall logistics performance.

Scalability and flexibility

Automation technologies provide scalability and flexibility in logistics operations. As companies grow or experience seasonal fluctuations in demand, automation can accommodate increased order volumes without the need for significant manual labor increases. Automated systems can adapt to changing customer requirements, allowing for agile and responsive logistics operations. By automating repetitive and time-consuming tasks, companies can allocate resources more effectively, allowing employees to focus on value-added activities and strategic decision-making.

With digital solutions and automated systems, businesses can better respond to disruptions in the supply chain — such as those caused by the coronavirus pandemic — or even predict unexpected spikes in demand.

It is important to note that the specific benefits of supply chain automation may vary depending on the industry, company size, and the extent of automation implemented. Let’s look at the challenges related to supply chain digitization.

Automation Challenges

Implementing a digital supply chain comes with its own set of challenges and risks. Awareness of these potential obstacles is essential to ensure a successful transition. Here are some key challenges and risks to consider:

Change management

Implementing digital transformation requires changes in processes, workflows, and mindsets. Resistance to change from employees and stakeholders can hinder the success of the transition. Effective change management strategies and clear communication are crucial.

Data security

With increased connectivity and data sharing, the risk of cyber threats and data breaches becomes a concern. Safeguarding sensitive information and ensuring robust cybersecurity measures are essential.

Return on investments (ROI)

Implementing a digital supply chain involves significant investments in technology infrastructure, training, and system integration. Calculating and demonstrating the return on investment may require careful evaluation and measurement of key performance indicators (KPIs).

Dependence on technology

Relying heavily on technology introduces the risk of system failures, technical glitches, or disruptions in connectivity. Contingency plans, backup systems, and disaster recovery strategies should be in place to minimize the impact of such events.

Supply chain transparency

While blockchain and digital technologies enable greater transparency, some suppliers or partners may hesitate to share information. Building trust and encouraging transparency across the supply chain can be gradual.

Integration complexity

Integrating digital technologies and legacy systems can be complex and time-consuming. Businesses must provide for compatibility issues, data migration, and system interoperability to avoid disruptions in the supply chain.

Vendor selection and collaboration

Choosing the right technology vendors and ensuring effective collaboration between partners can be challenging. Due diligence is necessary to select reliable and compatible technology providers that will support the organization's digital goals.

Skill gaps and workforce training

Adopting a digital supply chain requires a skilled workforce capable of operating and maintaining the new technologies. Upskilling or hiring talent with digital expertise may be necessary to fully leverage the benefits of digitalization.

Regulatory and compliance issues

Adhering to industry regulations and compliance standards can be complex in a digitalized supply chain. Understanding the legal and regulatory requirements specific to the industry and geography of operation is crucial in order to avoid legal complications.

Addressing these challenges and risks requires a strategic approach, strong leadership, and ongoing monitoring and evaluation. By proactively managing these obstacles, organizations can maximize the benefits of a digital supply chain and achieve sustainable business growth.

With that said, the company must have a comprehensive data management system to rely on — so, how to find a middle ground?

How SAP Helps Businesses to Find the Perfect Solution

The automated supply chain must optimally plan, prepare, and carry out all internal processes despite complex influencing factors and dynamic environmental changes. The aim here is not only to ensure reliable and timely task completion. It is also important to create suitable conditions for employees, use equipment and vehicles efficiently, reduce costs, and take ecological aspects into account.

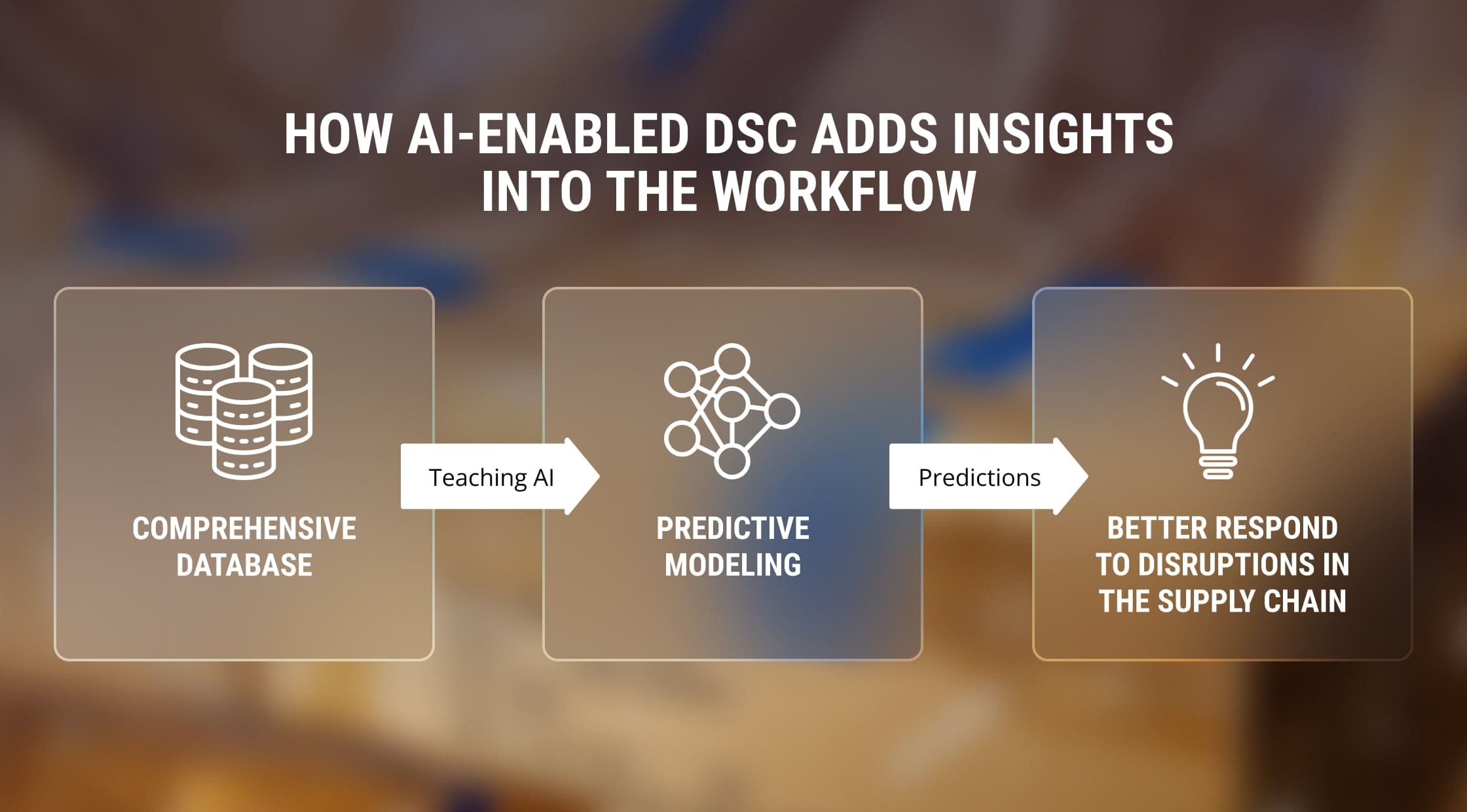

SAP Digital Supply Chain (DSC) is a comprehensive digital supply chain management software solution with embedded AI-based technologies. With it, supply chain operation becomes more agile in a market-oriented manner through intelligent, dynamic management of the supply chain. As a result, products reach customers faster and more cost-effectively, leading to leaner inventory management. The keys to this are high transparency in the supply chain, improved cooperation with suppliers, and forward-looking analysis using artificial intelligence.

With supply chain automation software, businesses can:

- Standardize processes as much as possible and avoid unnecessary variants.

- Create stable, rule-based processes that enable exception-based management.

- Focus the supply chain team on critical activities that deliver value.

- Improve handover between departments and eliminate redundancies.

- Introduce automation of decision-making processes and start with structured, recurring tasks.

- Measure the results and quality of processes with the right KPIs and process indicators.

Conclusion

Organizations can move from managing and connecting supply chain operations to using predictive analytics with machine learning, gleaning insights from collaborating with other departments or adopting an early failure detection approach. Automation makes the supply chain significantly more adaptable to changing customer requirements — which is why this so-called trend is here to stay.

Forward-looking models allow companies to compare different scenarios, understand potential outcomes, and identify the most effective alternatives for production. At LeverX, we have extensive experience in implementing supply chain automation software, which has helped many companies strengthen their business. Contact us to discuss your best-fit automation strategy!

How useful was this article?

Thanks for your feedback!

.webp)